CHAPTER 5

INTEGRITY OF METALS IN HOMOGENEOUS REACTOR MEDIA31

5-1. Introduction

The materials problems of aqueous fluid-fuel reactors are among the most challenging in modern technology. The temperatures of interest alone involve considerable departures from those areas for which scientific data and techniques for obtaining such data are available. However, these difficulties are minor compared with those encountered in the actual environment ultimately to be dealt with in an operating nuclear reactor. The radiation which results from the nuclear reactions may profoundly alter the chemistry of the fluids through the formation and decomposition of various chemical species; similarly, the corrosion and physical behavior of materials may be changed by radiation damage and transmutation. Consequently, materials for reactor construction cannot be adequately specified until their behavior in the ultimate reactor environment has been evaluated through in-pile radiation experiments. Such experiments can, however, be safely and meaningfully carried out only after extensive, careful out-of-pile investigation of the systems of interest. Thus a comprehensive experimental program is required involving facilities ranging from conventional laboratory apparatus to complex in-pile experiments with associated remote-handling and evaluation equipment.

The comprehensive character of the program is further justified by the high cost associated with reactor component failure. This high cost stems from the problems involved in repairing or replacing highly contaminated equipment. These problems are, of course, magnified by a failure which results in a release of radioactivity from the reactor, even though this release is only to a leaktight reactor containment chamber. Thus considerable effort to assure unusual reliability of the reactor system is appropriate.

The corrosion behavior of materials in the fluids of interest has also appreciably increased the scope of the program. Corrosion rates showing complex time dependence for as long as the first several hundred hours result from changes in fluid characteristics with time and/or the necessity of forming a protective oxide film. During this period the rate decreases with time in a quasi-exponential fashion. The corrosion rate then usually becomes linear and when the materials and environment are compatible is normally a few orders of magnitude lower than rates for the initial period. Flow conditions are also very important variables and so must be considered in all phases of the program; pump loops have fulfilled this requirement admirably. This time dependence of the corrosion rate complicates the interpretation of the data because it is a function of fluid flow, temperature, and fluid composition. Where tests arc run long enough to get good incremental measurements, the resultant linear rates provide a good basis for evaluating the effects of different variables on corrosion. However, meaningful corrosion rates cannot be obtained in short-term runs, in which case a better comparison can be made on the basis of the unit weight loss over the period. This variable is normally selected for comparing results in runs less than 200 hr.

5 .2. Experimental Equipment for Determining Corrosion Rates32

5-2.1 Out-of-pile equipment.

Static autoclaves, A variety of experimental equipment is required to determine the integrity of metals in aqueous homogeneous reactor media. The simplest apparatus consists of a glass flask in which various materials may be exposed to reactor fuel solutions at temperatures up to the atmospheric boiling point. At elevated temperatures and pressures, a static autoclave designed to withstand the temperature and pressure requirements is used with conventional or specially designed furnaces. A large number of tests may be rapidly and economically made in autoclaves prior to more extensive testing in dynamic corrosion test loops. The static autoclaves are used primarily for solution corrosion tests. Slurry corrosion tests are usually better conducted in equipment which provides agitation or forced circulation in order to prevent the slurry from settling into a dense bed.

Toroids. The toroid apparatus or rotator [1,2] provides a method of circulating fluids, as required to obtain data on the effect of fluid flow on corrosion rates, without the use of a pump. The toroid itself consists of a length of pipe bent into a circle with its ends joined. Pin-type corrosion specimens as well as a thermocouple well are inserted into the toroid through openings around the circumference. Each pin specimen is held firmly in a fitting, which also seals the opening in the pipe wall. When the environment is compatible, a Teflon (plastic) bushing is used to assist in holding the specimen, as well as to insulate it from the holder. Continuous pressure measurements may also be taken during operation by means of small-diameter tubing connecting the toroid to a pressure gauge or recorder.

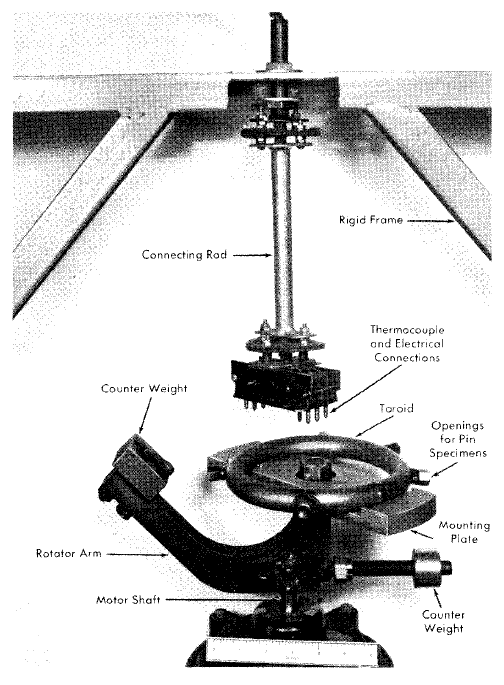

Fig. 5-1. Photograph of toroid rotator.

The fluid medium in the partially filled toroid is circulated by imparting a motion to the toroid similar to that by which liquid may be caused to swirl in a flask.

To attain the necessary circular motion, the toroid is attached to a horizontal mounting plate which, in turn, is attached at its center (by means of a bearing) to the vertical shaft of a rotator arm. The rotator arm is, in turn, mounted on the shaft of a variable-speed motor, as shown in Fig. 5-1. The toroid is prevented from rotating about its own axis by means of a connecting rod installed between the toroid plate and an external rigid frame. Dynamic balancing of the unit is required for operation at high speeds (500 to 1000 rpm), and a counterweight is provided for this purpose. Flow velocities up to 30 fps are obtained in the unit now in use. A heating system, which consists of electric heating wire or elements wrapped around the toroid, provides for operation at elevated temperature and pressure. The entire apparatus is relatively inexpensive and fills the need for a laboratory-scale dynamic corrosion test.

In view of the fractional filling of the toroid, which results in ”slug flow," corrosion attack rates based on the elapsed time of operation may be corrected to account for the time of immersion in the circulating fluid. This is usually required when corrosion rates obtained in a toroid are being compared with those obtained in the dynamic corrosion test loops described below.

The toroid rotator can be used in the study of solutions and slurries. It has been particularly useful for slurries because of the small amount of material required. The exploration of many slurry variables has been possible with amounts of material (50 to 100 g) easily prepared in the laboratory.

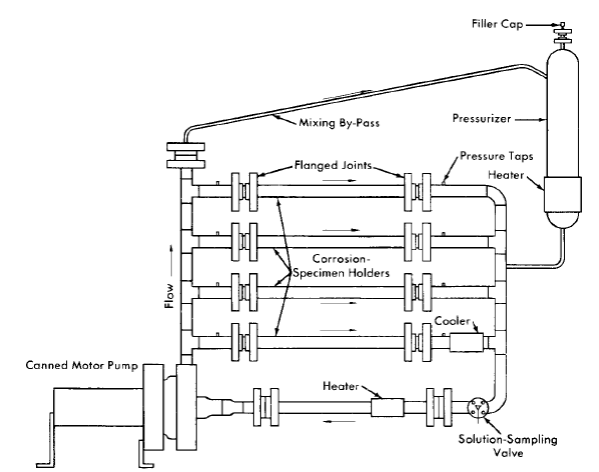

FIG. 5-2 . Dynamic solution corrosion test loop .

Dynamic corrosion test loops. Dynamic solution corrosion test loops designed to operate under the various conditions proposed for homogeneous reactor operation are the principal experimental equipment used for out-of-pile tests. One such loop is shown diagrammatically in Fig. 5-2, in which the flow is divided between a number of parallel channels in which corrosion test specimens can be exposed. Several sets of specimens may be exposed to several flow conditions or a larger variety of specimens to a given set of flow and solution conditions. Loops of various designs have been constructed for other specific purposes [3,4].

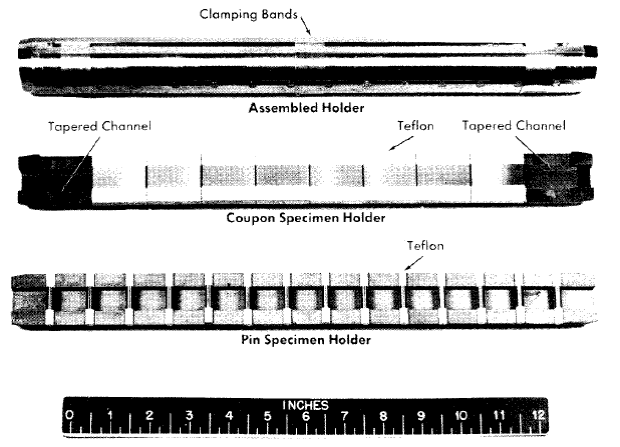

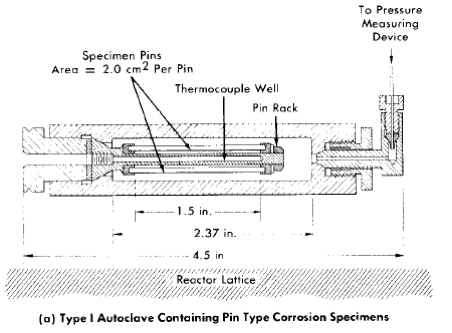

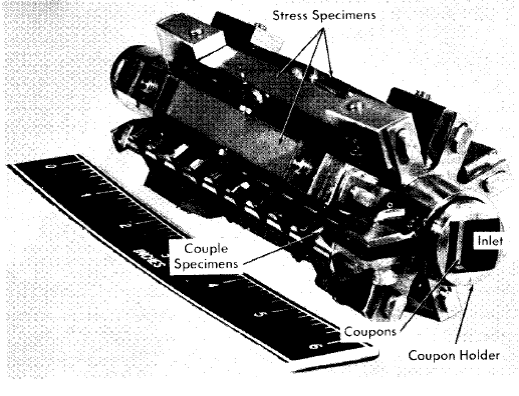

Fig. 5-3. Pin and coupon specimen holders.

The test loop consists of a circulating pump, pipe loop, and a pressurizer. The circulating pump is a Westinghouse model 100A canned-motor centrifugal type [5]. This pump delivers 100 gpm at a 250-ft-head and is constructed for operation at pressures up to 2500 psi. The loop and pressurizer are heated by means of electric elements cast in aluminum around the outside of the piping.

The loops are usually constructed of Ij-in. schedule-80 pipe. Flanged joints are used liberally in the loop construction to provide easy access for inspection and for connection of special experimental equipment. For simplicity, economy, and elimination of crevices, a simple butt joint using lap-joint flanges, bearing rings, and a metal gasket [6] is generally used. The test specimens are exposed in split-channel holders inserted in flanged-pipe sections as shown.

The pressurizer, which consists of a vertically mounted section of 4- to 6-in.-diameter pipe, serves several functions. It provides system overpressure, contains space for solution expansion in the loop during heatup, contains space for gas that may be required for solution stability and/or corrosion studies, and serves as a reservoir for excess solution for samples removed during operation.

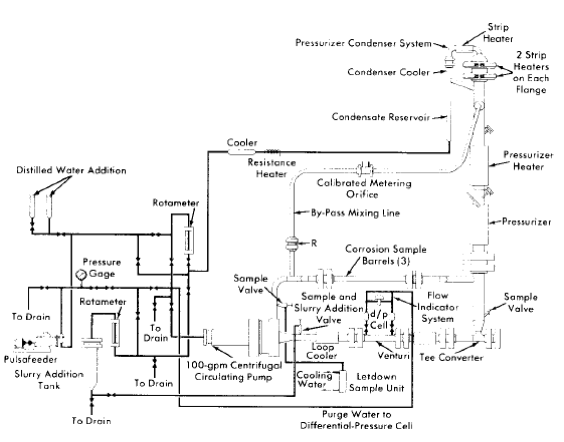

Fig. 5-4. Dynamic slurry corrosion test loop.

Two types of holders used for exposure of test specimens in the loop are shown in Fig. 5-3. The pin specimen holder shown is used to test a variety of materials at a uniform bulk fluid flow velocity. Pin-type specimens inserted in the holes are exposed to the solution flowing through the channel when the holder is assembled. Teflon sleeves on the ends of the pins serve as compressible gaskets to keep the specimens from rattling in the holder during the test and to insulate the specimens from the holder. Figure 5-3 also shows the specimens and holder used in determining the effect of velocity on corrosion. In this holder, flat coupon specimens form a continuous septum down the center of the tapered channel, so the bulk fluid flow velocity increases as the solution traverses the holder. Velocity-effect data thus obtained may be used in the design of reactor piping systems if the data are confirmed by loop experience.

In the dynamic slurry corrosion test loop [7], shown in Fig. 5-4, the pump discharge flow is directed through the bottom portion of the pressurizer to minimize settling and accumulation of slurry particles which would occur in this region if the pressurizer were connected as in the solution test loop. As shown in this figure, a condenser is installed in the pressurizer vapor space to supply clean condensate required to continuously purge the pump bearings and prevent slurry accumulation, which would result in excessive bearing wear. The flow of steam or steam-gas mixture through the condenser is by thermal convection. The condensate thus produced flows to the rear of the pump as a result of the static pressure difference between these two points in the system.

Fig. 5-5. In-pile rocking autoclaves.

A slurry addition device is also incorporated in the loop so that slurry may be charged at elevated temperature and pressure. This device consists of a reservoir tank connected at its bottom to the main loop piping. The slurry may be added batchwise to the tank and, after the top flange is closed, may be forced into the loop by differential pressure, with the slurry being replaced by an equal volume of water from the condensate system. A high-pressure rotometer and regulating valve are provided in the addition system for metering and adjusting this flow of condensate so that flow to the pump bearings is maintained. To ensure purge-water feed to the pump bearings and to provide positive feed of condensate for the slurry addition system in the event of a loss of static pressure differential, a pulsafeeder pump is incorporated in the condensate circuit and may be used as required.

As an aid in monitoring the density and thus the concentration of the circulating slurry, venturi type flowmeters with high-pressure-differential pressure cells are used in the slurry loop.

5-2.2 In-pile equipment.

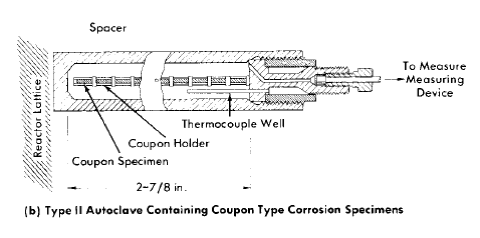

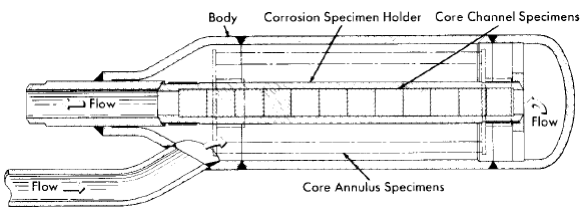

Rocking autoclaves. To obtain information on the behavior of fuels and materials under reactor conditions, experiments have been carried out in the Graphite Reactor and Low Intensity Test Reactor at ORNL and in the Materials Testing Reactor at NRTS [8-12] using small autoclaves or bombs. The autoclaves used for such tests are shown in Fig. 5-5 [9]. The autoclave, in a specially designed container can and shield plug assembly, is rocked by the mechanism at the face of the reactor shield. The rocking is designed to keep the solution mixed, to maintain equilibrium between liquid and vapor phases, and to keep all surfaces wet. The latter provision prevents the formation of local hot spots by the high gamma fluxes or localized recombination reaction with resultant explosive reaction of the hydrogen and oxygen formed by radiolytic decomposition of water. The assembly is so designed that the autoclave can be retracted into a cadmium cylinder, thereby substantially reducing the flux exposure. This minimizes the necessity for reactor shutdowns in case of minor experimental difficulties and is useful for obtaining data. The necessary electrical and cooling lines are carried to the face of the reactor shield through the container can and a shield plug. In addition, a capillary tube, filled with water, connects the autoclave to a pressure transducer gauge. By this means a continuous record of the pressure in the autoclave is obtained. In cases where a quantitative relationship exists between the corrosion reaction and consumption or production of a gas, the pressure measurements, suitably corrected, provide a measure of the generalized corrosion rate.

Pump loops. An in-pile loop [13] is similar to all forced-circulation loops; it consists of a pump, pressurizer, circulating lines, heaters and coolers, and associated control and process equipment. The circulating pump, designed at ORNL [14-16], is a canned-rotor type which delivers 5 gpm at a 40-ft head at pressures up to 2000 psig.

Table 5-1

Physical Data for Typical in-Pile Loop

| I. Loop volume | |

| 1. Pump rotor chamber | 160 cc |

| 2. Pump scroll | 107 cc |

| 3. Core | 300 cc |

| 4. Loop pipe (3/8 in. Sch. 40) | 440 cc |

| 5. Pressurizer (1-1/2 in. 8ch. 80) Total | 750 cc |

| Total | 1757 cc |

|

|

| II. Pipe size | |

| 1. Main loop | 3/8 in. Sch. 40 |

| 2. Core | 2 in. Sch. 80 |

| 3. Pressurizer | 1-1/2 in. Sch. 80 |

| 4. Pressurizer bypass line | 1/4in. X 0.0949 in. wall tubing |

| 5. Pump drain line | 0.090 in. OD-0.050 in. ID tubing |

| 6. Loop drain line | 0.090 in. OD-0.050 in. ID tubing |

| 7. Gas addition line (pressurizer) | 0.060 in. OD-0.020 in. ID tubing |

| 8. Pressure transmitting line (pressurizer) | 0.080 in. OD-0.040 in. ID tubing |

|

|

| III. Flow rates | |

| 1. Main loop | 5gpm (8.5 fps) |

| 2. Pressurizer bypass line | 6 cc/sec (1.2 fps) |

| 3. Pressurizer | 6 cc/sec (0.034 fps) |

| 4. Tapered channel coupon holder | 5 gpm (variable : 10-45 fps) |

|

|

| IV. Capacities* of loop heaters and coolers | |

| 1. Main loop heater | 3000 watts |

| 2. Main loop cooler | 6000 watts |

| 3. Pressurizer preheater | 1500 watts |

| 4. Pressurizer jacket heater | 400 watts |

|

|

| *Values shown are maximum. |

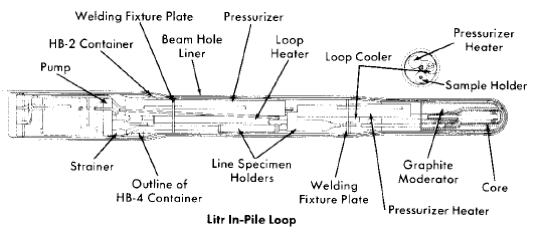

The loop assembly and 7-ft-long container are shown in Fig. 5-6. Some of the physical data for a typical loop are summarized in Table 5-1 [17]. The loop components are usually constructed of type-347 stainless steel, although one loop has been constructed in which the core section was made of titanium and another was made entirely of titanium. The loop container, 7 ft long, is 6 in. in diameter at the core end and 8 in. at the pump end and is designed to withstand a pressure surge of 500 psi in case of a sudden failure of a loop component. All electrical and process lines are carried through the pump end of the container through sealed connectors and then through the shield plug to the "valve boxes" at the face of the reactor. These valve boxes are sealed, shielded containers in which are located process lines and vessels, valves, samplers, and sensing devices for the instrumentation [13]. The equipment in the boxes is used with successive loops, whereas each loop is built for a single experiment and completely dismantled by hot-cell techniques thereafter [18]. Samples of the circulating solution for analysis are withdrawn through a capillary line during operation, and reagent additions can also be made if desired. A capillary connection to the pressurizer is used to follow pressure changes in the loop and to make gas additions when necessary. As in the case of the in-pile autoclaves, previously described, the pressure data can be used to follow a generalized average corrosion rate for all the materials in the loop as the operation proceeds.

Fig. 5-6. In-pile loop assembly drawing.

Specimens can be exposed in the pressurizer, in holders in the line just beyond the pump outlet, and in the core. The specimens in the core inside the tapered-channel holder and in the annulus around it are exposed to the solution in which fissioning is taking place and to direct pile radiation. Duplicate specimens in the in-line holders are exposed to the same solution in the absence of the fissioning and direct pile radiation. As in the out-of-pile loops discussed previously, the tapered-channel coupon holders are used to study velocity effects. The core specimen holder is shown in place in Fig. 5-7. Figure 5-8 is a photograph of a core corrosion specimen assembly in which can be seen coupled coupons on a rod assembly, as well as coupons in the tapered-channel holder and stress specimens in the core annulus. Although not shown, impact and tensile specimens are also sometimes exposed in the core annulus.

The loops must be adequately instrumented [19] to provide accurate measurements of loop temperatures, pressurizer temperatures, and pressures within the loop. The quantity of oxygen and hydrogen in the pressurizer is obtained from the pressurizer temperature and pressure measurements. Electrical power demands of the loop heater furnish a measure of over-all fission power and gamma heating within the loop. Since the loop, in effect, becomes a small homogeneous reactor operating sub-critically, when enriched fuel solution is being circulated many automatic safety interlocks are used to prevent the possible release of radioactive material.

Fig. 5-7. Core holder for coupon specimens.

Fig. 5-8. Core specimen array.

Remote-handling equipment. After exposure in the reactor, dismantling of the loops [18] and autoclaves [20], and subsequent examination of the test specimens and component parts must be done in hot cells with remote handling equipment. Prior to removal from the reactor, the fuel solution is drained from the loop or autoclave and all radioactive gas is vented. The loop or autoclave is then withdrawn into a shielded carrier and separated from its shield plug to facilitate handling. It is then removed to the hot cell facilities for dismantling and examination.

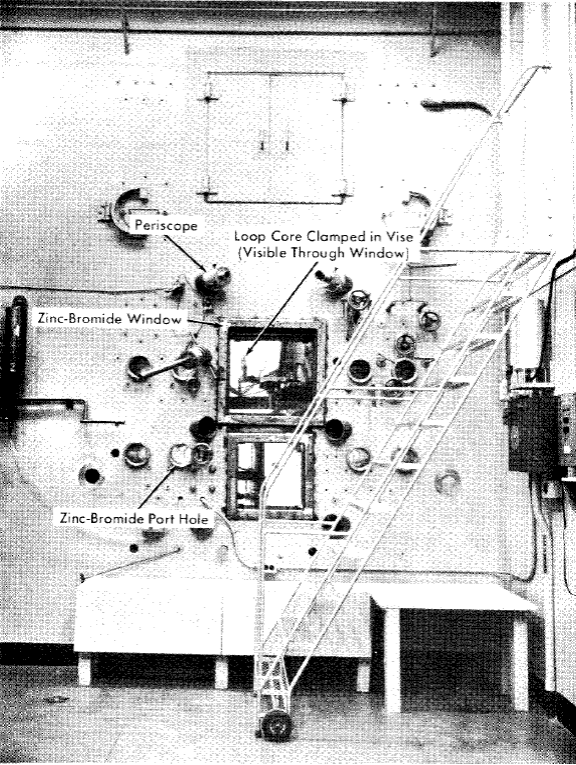

Fig. 5-9. Exterior view of in-pile loop dismantling facility.

The operating face of the hot cell for dismantling an in-pile loop is shown in Fig. 5-9. An abundance of 1- and 2-in-diameter sleeves are included for insertion of remote-handling tools; two large zinc-bromide windows, eight 6-in. zinc-bromide portholes, and six periscope holes are provided for viewing. The usual hot-cell services, such as hot drain, metal-recovery drain, hot exhaust, vacuum, air, water, and electricity, are provided.

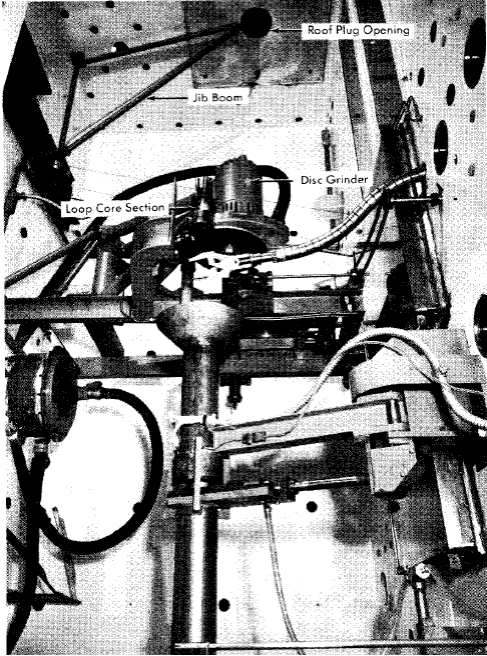

Fig. 5-10. Interior view of in-pile loop dismantling facility.

The loop in its container can is lowered from its carrier, through a roof-plug opening, into the cell, where it is clamped in a chuck which rotates the assembly while a disk grinder cuts off the rear section of the container. A jib boom is used to withdraw the loop from the container, and various sections of the loop are then cut out by means of a disk grinder. Figure 5-10 is a photograph of the dismantling equipment in the hot cell.

The severed loop sections are then removed to a remote-examination facility [21] where the more exacting tasks of removing, examining, and photographing loop components, as well as weighing individual test specimens, required to determine corrosion damage, are carried out. Hot-cell techniques are again used, with the aid of specially designed remote handling equipment.

5-3. Survey of Materials

5-3.1 Introduction.

To determine the corrosion resistance of many different materials to uranium-containing solutions, a large number of screening tests have been performed. These tests were carried out either in pyrex flasks at the boiling point of the solution or in stainless steel autoclaves or loops at 250°C. Oxygen or air was bubbled through the atmospheric boiling solutions, whereas at 250°C the test solutions were pressurized with 100 to 200 psi oxygen. The corrosion rates of the materials were determined from weight losses of test specimens after the corrosion products had been removed from their surfaces by an electrolytic descaling process [22]. The results of the tests are presented in the following sections. All tests were carried out in the absence of radiation.

The stainless steel designations are those of the American Iron and Steel Institute. The composition of most of the other materials is listed in Engineering Alloys [23] and those not so listed are included in Table 5-2. All the materials were tested in the annealed condition except in the cases where parentheses follow the alloy designation, in Table 5-3. The number thus enclosed is the hardness of the material on either the Rockwell C (RC) or Rockwell B (RB) scale.

5-3.2 Corrosion tests in uranyl carbonate solutions.

Since uranium trioxide is more soluble in lithium carbonate solutions at high temperatures than in solutions of other carbonates, the corrosion resistance of the materials was determined only in the lithium carbonate system. All corrosion tests were carried out in stainless steel loops at 250°C. The test solution was prepared by dissolving 0.03 moles of uranium trioxide per liter of 0.17 m Li2CO3 and passing carbon dioxide through the solution until the uranium was in solution. The solution was then circulated for 200 hr in a loop pressurized with 700 psi carbon dioxide and 200 psi oxygen. The flow rate of the solution was 20 fps. Table 5-3 shows the materials that were tested and the ranges of corrosion rates that were observed.

Thus the corrosion resistance of all the metals and alloys tested was good with the exception of aluminum, copper, and most of the nickel- or cobalt-base alloys. The acceptable alloys developed films that would have prevented further corrosion had the tests been continued longer. Data presented elsewhere [24] show that even the carbon steels and iron would be satisfactory materials in carbonate systems. The fact that the carbonate solution is approximately neutral is undoubtedly the reason for the non-aggressive nature of the solution.

Table 5-2

The Composition of Several Materials Tested for Corrosion Resistance

| Alloy designation |

|

|

Composition, w/o |

|

||

|

Cr | Ni | C | Fe | Mn | Other |

| 202 | 17-19 | 4-6 | 0.15 max | bal. | 7.5-10 |

|

| 309 SCb | 22-26 | 12-15 | 0.08 max | bal. | 2.0 max. | Nb 8 x C min |

| 318 | 17-19 | 13-15 | 0.08 max | bal. | 2.5 max | Nb 10 x C min |

| SRF 1132 | 12 | 13 |

|

bal. |

|

Cu 5.5, Mo 7 |

| Carpenter 20 Cb | 20 | 29 | 0.07 max | bal. | 0.75 | Nb/Ta 8x C min |

|

|

|

|

|

|

Cu 3, Mo 2 |

| Croloy 1515 N | 14.7-18.0 | 13.5-16.5 | 0.15 max | bal. | 2.0 max | Mo 1.25-1.85, W 1.00-1.85, |

|

|

|

|

|

|

Nb/Ta 0.08-0.13 |

| 322W | 17 | 7 | 0.07 | bal. | 0.5 | Ti 0.7, Al 0.2 |

| 329 | 25-30 | 3-5 | 0.10 max | bal. |

|

Mo 1-l.5 |

| CD4MCu | 25-27 | 4.75-G.00 | 0.04 max | bal. | 1.0 | Mo 1.75-2.75 |

|

|

|

|

|

|

Cu 2.75-3.25 |

| Croley 16-1 | 14.5-16.5 | 0.80-1. 25 | 0.03 max | bal. |

|

|

| Allegheny 350 | 17 | 4.2 | 0.08 | bal. | 0.60 | Mo 2.75 |

| Rexalloy 33 | 33 |

|

2.25 | 2 max |

|

W 17, Co 44 |

| Armco GT-45 |

|

|

0.17 | bal. |

|

|

| Titanium 45 A |

|

|

|

|

|

Ti 99+ |

| Titanium AC |

|

|

|

|

|

Al 3, Cr 5, bal. Ti |

| Titanium AM |

|

|

|

|

4 | Al 4, Mn 4, bal. Ti |

| Titanium AT |

|

|

|

|

|

Al 5, Sn 2.5, bal. Ti |

| Titanium AV |

|

|

|

|

|

Al 6, V 4, bal. Ti |

| Titalloy X |

|

|

0.02 |

|

|

Al 1.6, V 1.9, bal. Ti |

| Titalloy Y |

|

|

0.02 |

|

|

AI 1.2, bal. Ti |

| Titalloy Z |

|

|

0.01 |

|

|

AI 2.4, bal. Ti |

| Zircaloy 1 |

|

|

|

|

|

Sn 2.5, bal. 'Zr |

| Zircaloy 2 |

|

|

|

|

|

Sn 1.5, Fe 0.07-0.2, Cr 0.02-0.15, Ni 0.03-0.08 |

| Zirconium-tin |

|

|

|

|

|

Sn 5, bal. Zr |

Table 5-3

Corrosion Rates op Several Alloys in a Solution OF 0.17 m Li2CO3 Containing 0.03 m UO3 at 250°C

Pressurizing gases: 700 psi CO2 and 200 psi O2.

Time: 200 hr. Flow rate: 20 fps.

| Metal or alloy | Range of avg. corrosion rates, mpy |

| Austenitic stainless steels |

|

| 202, 302B, 304, 304L, 309SCb, 310S, 316, |

|

| 318, 321, 347 | 0.8-2.6 |

| Carpenter 20, Carpenter 20 Cb, Incoloy, |

|

| Worthite | 2.4-4.0 |

|

|

| Ferritic and martensitic stainless steel |

|

| 322 W, 410, 410 (cast), 414, 416, 420, 430, |

|

| 431, 440C, 446, 17-7 PH | 0.8-2.4 |

| 416 (36 RC), 440C (56 RC) | 3.6--5.3 |

|

|

| Titanium alloys |

|

| 55A, 75A, 100A, 100A, AC, AM, AT, A V | 0.3-0.6 |

|

|

| Other metals and alloys |

|

| Zirconium and Zircaloy-S | <0.1 |

| Hastelloy C, Nionel, gold, niobium, platinum | 0-0.9 |

| Armco Iron, AISI-C-IOlO, AISI-C-1016 | 6.4-7.8 |

| Inconel, Inconel X, nickel, Stellite 1, 2, 3, |

|

| 98M2, Haynes Alloy 25, copper | 16-90 |

| Aluminum | >1000 |

5-3.3 Corrosion tests in uranyl fluoride solutions.

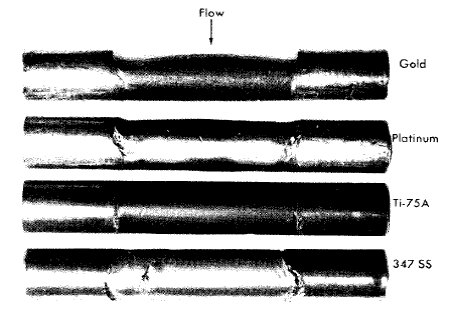

In contrast to uranyl carbonate solutions, uranyl fluoride solutions are acid, and in general the corrosivity of the fluoride solutions is much greater than that of the carbonate solutions. To determine the relative corrosion resistances of many different metals and alloys, a 0.17 m UO2F2 solution was used. Tests were performed at 100 and 250°C in static systems and at 250°C in loops. The static tests were continued for periods up to 1000 and 2000 hr. The dynamic tests lasted for 200 hr, and the flow rate of the solution past the specimens was 10 to 15 fps. The results of the dynamic tests are shown in Table 5-4.

Table 5-4

The Corrosion Rates of Several Alloys in 0.17 m UO2F2 AT 250°C

Pressurizing gas: 200 psi O2.

Time: 200 hr. Flow rate: 10 to 15 fps.

| Metal or alloy | Range of avg. corrosion rates, mpy |

| Austenitic stainless steels |

|

| 304, 304L, 3098Cb, 310, 316, 316L, 318, |

|

| 321, 347 | 4-13 |

|

|

| Ferritic and martensitic stainless steels |

|

| 322W, 430, 443, 17-4 PH | 3.5-5.0 |

| 416 | >2000 |

|

|

| Titanium and zirconium alloys |

|

| 55A, 70A, 100A, 150A | 0.01-0.25 |

| AC, AM, AT | 5.6-7.7 |

| Zirconium, Zircaloy-2 | > 2000 |

|

|

| Other metals |

|

| Gold, platinum | < 0.5 |

| Niobium | > 1000 |

All the stainless steels except type 416 showed low corrosion rates under the conditions of test. Other experiments showed that most of the corrosion occurred in about the first 100 hr of exposure, during which time a protective coating formed on the steel. After the coating formed, corrosion rates in the range of 0.1 mpy or less were observed (provided the flow rate was not too high). The static corrosion tests of longer duration verified the dynamic results. Thus, had the dynamic tests reported in Table 5-4 lasted for 1000 hr, the average corrosion rates would have been approximately one-fifth of those shown.

At high temperatures, all the stainless steels corrode at high constant rates if the flow rate of the solution exceeds a certain value which depends on the concentration of the solution and the temperature (to be discussed in the next section). In 0.17 m UO2F2 at 250°C this critical value is 20 to 25 fps.

As expected, zirconium and zirconium alloys showed no resistance to attack by uranyl fluoride solutions at high temperatures. In fact, other tests have shown that as little as 50 ppm fluoride ions in uranyl sulfate solutions leads to appreciable attack of zirconium [25]. On the other hand, titanium demonstrated high resistance to uranyl fluoride solutions. Tests with more highly concentrated uranyl fluoride solutions have shown the corrosion rate of titanium to be low. The titanium alloys showed higher rates, ranging from 5 to 8 mpy. However, in crevices where oxygen depletion occurs, titanium and its alloys are severely attacked [26].

No nickel- or cobalt-base alloys were tested under dynamic conditions. Those tested at 250°C in autoclaves include D Nickel, Chromel P, Stellite 98M2, and nickel; all showed rates in excess of 18 mpy during 1000- to 2000-hr tests. At 100°C nickel corroded at a rate greater than 100 mpy and Monel corroded at 7 mpy; the other above-listed materials, Elgiloy, Hastelloys C and D, Illium R, and Inconel, corroded at rates less than 1.5 mpy.

Gold, platinum, and tantalum were practically unattacked by the uranyl fluoride at 250°C; the resistance of tantalum was unexpected. Niobium was heavily attacked.

It is seen from the foregoing that several metals, including most of the stainless steels, have adequate corrosion resistance to uranyl fluoride solutions if the flow rate of the solution is not too great. Uranyl fluoride cannot be used in a two-region reactor, however, because zirconium and uranyl fluoride solutions are incompatible. Another possible difficulty of uranyl fluoride solutions in any system is the fact that the vapor above the acid uranyl fluoride system may contain some hydrofluoric acid which, if present, would present a serious corrosion problem.

5-3.4 Corrosion tests in uranyl sulfate solutions.

Many corrosion tests discussed in detail in HRP progress reports [27] have been carried out in uranyl sulfate solutions under different conditions of temperature, uranium concentration, flow rate, etc. Table 5-5 shows representative corrosion rates of a number of materials obtained in 0.17 mUO2SO4 at 250°C in stainless-steel loops during a 200-hr. exposure. The flow rate of the solution past the specimens was 10 to 15 fps. Static tests, the results of which are not included in the table, have also been carried out at 100 and 250°C and generally lasted for 1000 to 2000 hr. The results obtained in static systems generally confirmed the dynamic results, although the corrosion rates observed in static systems were less than those measured in dynamic systems.

Table 5-5

The Corrosion Rates of Several Alloys in 0.17 m UO2SO4 at 250° C

| Metal or alloy | Range of avg. corrosion rates, mpy |

| Austenitic stainless steels |

|

| 202, 302, 302B, 303, 304, 304L, 309SCb, |

|

| 31OS, 316, 316L, 318, 321,347, Carpenter |

|

| Alloys 10, 20, 20Cb, Croloy l5l5N, |

|

| Durimet, Incoloy, Multimet, Timken |

|

| 16-25-6, Worthite | 14-65 |

| SRF 1132 | 190 |

|

|

| Ferritic and martensitic stainless steels |

|

| Armco 17-4 PH (37 RC), Armco 17-7 PH (43 RC) | 3.1-4.9 |

| 322W, 322W (27-38 RC), 329, 430, 431, 431 (43 RC), 446, Armco |

|

| 17-4 PH, CD4l\fCu, Allegheny 350, Allegheny |

|

| 350 (38-43 RC), Croley HH, Frogalloy | 6.35 |

| 410, 410 (43 RC), 414, 416, 416 (37 RC), 420, Armco 17-7 PH | 46-81 |

| 420 (52 RC), 440 C | 100-430 |

|

|

| Titanium and zirconium alloys |

|

| 45A, 55A, 75A, l00A, 15OA, AM, Titalloy X Y and Z | 0.01 |

| AC,AT,AV | 0.03-0.12 |

| Zircaloy-l and -2, zirconium, zirconium-tin | < 0.01 |

|

|

| Nickel and cobalt alloys |

|

| Hastelloy R-235, Inconel X, Stellite 1 | 77-88 |

| Hastelloy C and X, Haynes Alloy 25, |

|

| Inconel, Stellite 3, 6, and 98M2 | 120-340 |

|

|

| Other metals |

|

| Gold, platinum | < 0.1 |

| Niobium | 6.7 |

| Sapphire | 17 |

| Quartz | 58 |

| Pyrex glass | 730 |

The data presented in Table 5-5 show only the relative corrosion resistance of different classes of alloys and need further clarification. From the results reported in the table, and from many other static and dynamic tests of longer duration, the following conclusions can be drawn. All the austenitic stainless steels except SRF 1132, 316, and 316L behaved essentially alike; all corroded rapidly and uniformly for about the first 100 hr, during which time a protective coating formed (provided the flow rate was less than 20 fps). Once the film formed, corrosion rates less than 0.1 mpy were observed. The extent of attack during film formation varied somewhat from run to run, and there was no consistent difference from one austenitic stainless steel to the other. Thus, even though the rates reported in Table 5-5 are high, the continuing rates are very low; as a class, the austenitic stainless steels are satisfactory materials for containing uranyl-sulfate solutions at reasonable flow rates. Types 316 and 316L showed a tendency toward intergranular attack, and SRF 1132 did not develop a highly protective coating.

Of the ferritic and martensitic stainless steels, types 410, 416, 420, and 440C in all heat-treated conditions were completely unsatisfactory. The corrosion rates of these alloys were nearly constant with time, and the attack was very irregular. Although the precipitation-hardenable steels, 322W, 17-4 PH, and 17-7 PH, showed very low corrosion rates after the formation of the protective film, all displayed a tendency toward stress-corrosion cracking in their fully hardened conditions. Croloy 16-1 demonstrated reasonable corrosion resistance in short-term tests, but long static tests showed the material to be susceptible to intergranular attack in uranyl sulfate solutions. The other ferritic and martensitic stainless steels corroded in the same fashion as did the austenitic stainless steels; that is, after a protective film formed the corrosion rates were in the range of 0.1 mpy. From a corrosion standpoint these materials have adequate corrosion resistance for use in high-temperature uranyl sulfate solutions.

Titanium, zirconium, and all of their alloys were extremely resistant to attack by uranyl sulfate solutions at all concentrations, temperatures, and flow rates. In fact, corrosion damage was so small that it was difficult to detect weight changes of the specimens with a standard analytical balance. These alloys will be discussed further in Sections 5-5 and 5-6.

Most of the nickel- and cobalt-base alloys listed in Table 5-5 were rapidly attacked by high-temperature uranyl sulfate solutions. The two exceptions were Hastelloy R-235 and Elgiloy. Hastelloy R-235 resembled an austenitic stainless steel in that it developed a film and corroded practically no further. Although Elgiloy corroded only slightly, it was extremely susceptible to stress-corrosion cracking in high-temperature uranyl-sulfate solutions. Thus, of the alloys listed, only Hastelloy R-235 could be considered for use in high-temperature uranyl sulfate solutions. On the other hand, most of the alloys were resistant to uranyl sulfate solutions at 100°C; corrosion rates less than a few tenths of a mpy were observed. It is particularly significant that many of the very hard alloys, such as the Stellites, are resistant at the lower temperature; in many applications, such as pump bearings, temperatures no greater than 100°C are required.

In dynamic tests platinum and gold were resistant to attack under all conditions, but niobium corroded at an appreciable rate, about 7 mpy at 15 fps. The corrosion rate of niobium depended on the flow rate of the solution, and at higher flow rates somewhat higher corrosion rates were observed. Static tests showed that tantalum and chromium are corroded only slightly under most conditions. If the solution contained dissolved hydrogen, tantalum was seriously embrittled; highly oxygenated uranyl-sulfate solutions at temperatures above 250°C oxidized chromium to the soluble hexavalent state, and under these conditions the rate of attack was several mils per year.

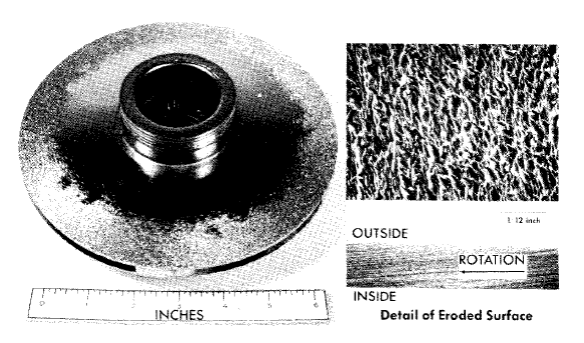

A number of non-metallic substances were statically tested in 0.17 m UO2SO4 at 100°C. Those tested included various grades of sintered alumina and graphite, sapphire, silicon carbide, sintered titania and zirconia, and quartz. All corroded at rates of less than 3 mpy, except for one very impure grade of sintered alumina which corroded at 124 mpy. In fact, the corrosion resistance of the sintered alumina was higher, the higher the purity. In static tests at 250°C in 0.17 m UO2SO4, the corrosion rate of pure sintered alumina was 3 mpy; sapphire corroded at the rate of 3.6 mpy. In dynamic tests under the same conditions, sapphire corroded at 17 mpy, quartz at 58 mpy, and Pyrex glass at 730 mpy. The high corrosion rates of quartz and Pyrex glass show why glass-lined equipment cannot be used for high-temperature experimental work. In addition to the attack on the glass, the resultant silicates cause precipitation of uranium.

5-3.5 Conclusions.

Type-347 stainless steel has been the basic material of construction in most homogeneous reactor programs. It has serious limitations, particularly from the corrosion standpoint, but in consideration of the additional important factors of cost, availability, and experience with its use, it appears a suitable material. The excellent corrosion resistance of titanium and several of its alloys makes them very useful in special applications, particularly where the limitations of the stainless alloys make their use impractical. Cost, availability, and a recently observed auto ignition reaction in oxygen-containing environments are serious limitations to the use of titanium in pressure-containing equipment (see Article 5-8.5). Zirconium and zirconium-rich alloys are unique materials for the core vessel of a two-region breeder.

The behavior of these materials in homogeneous reactor fluids is described in detail in subsequent sections of this chapter.

5-4. Corrosion of Type-347 Stainless Steel in Uranyl Sulfate Solutions33

5-4.1 Introduction.

The decision to use type-347 stainless steel as the major material of construction and a uranyl sulfate solution as the fuel for HRE-1 and HRE-2 was based, at least in part, on the demonstrated compatibility of the two components and on the fact that the technology of the austenitic stainless steels was well developed. Articles 5-4.2 through 5-4.7 present the results of an extensive investigation of the corrosion of type-347 stainless steel in uranyl sulfate solutions in the absence of ionizing radiation, and in Article 5-4.8 the effect of ionizing radiation on the corrosion of stainless steel is discussed. Further details are reported in the HRP quarterly progress reports [28].

All the results reported in this section were obtained with solutions containing between 50 and 1000 ppm oxygen to prevent reduction and precipitation of uranium; the precipitation of uranium as U3O8 leads to the formation of sulfuric acid which attacks stainless steel at a very high rate at the temperatures of interest. A consequence of these phenomena is the possibility of localized attack in crevices where oxygen depletion can occur.34 Other forms of localized attack have been investigated, but except for stress-corrosion cracking in the presence of chloride ions (discussed in Section 5-9) no serious problems have arisen. Thus, even with unstabilized stainless steels that have been sensitized by appropriate heat treatment, no severe intergranular attack in uranyl-sulfate solutions occurs. The coupling of such noble metals as gold and platinum to type-347 stainless steel does not result in accelerated attack of the stainless steel.

5-4.2 Effect of temperature.

When type-347 stainless steel is placed in a uranyl-sulfate solution at temperatures up to 100°C, the steel retains its metallic luster, and only after long periods of time does it develop a very thin tarnish film. At higher and higher temperatures the film becomes progressively heavier, and in the temperature range 175 to 200°C a quite heavy black scale forms on the surface of the steel in about 100 hr. Up to about 175°C the film that forms is non-productive, and the corrosion rate is dependent on the composition of the solution and independent of the flow rate past the steel surface. Some typical corrosion rates in this temperature range are presented in Table 5-6.

Table 5-6

Corrosion Rate op Type-347 Stainless Steel in

Uranyl Sulfate Solutions at 100 to 175°C

Solution composition |

Temperature, °C |

Corrosion rate, mpy |

| 0.02 m UO2SO4 } | 100 | 0.25 |

| 0.006 m H2SO4 } | 150 | 0.96 |

|

|

|

| 0.04 m UO2SO4 } | 150 | 0.87 |

| 0.006 m H2SO4 } | 175 | 5.4 |

| 0.005 m CuSO4 } |

|

|

|

|

|

| 1.3 m UO2SO4 | 100 | 0.40 |

|

125 | 0.80 |

|

150 | 2.8 |

|

175 | 18.0 |

The heavy film that forms in the temperature range 175 to 225°C offers some protection to the underlying steel, but in most cases the protection is poor. At higher temperatures a heavy scale forms fairly rapidly on the stainless steel, and once it has been established it affords essentially complete protection against further corrosion, provided the flow rate of the solution is not too great.

The protectiveness of the film appears to be related to its composition. At temperatures up to 175°C the scale, as determined by x-ray diffraction, is composed of mixed hydrated ferric and chromic oxides. At higher temperatures the amount of hydrated oxide decreases, and the amount of anhydrous alpha ferric oxide containing chromic oxide in solid solution increases. At 250°C and higher, only the anhydrous oxide is found in the protective scale.

The amount of metal that dissolves during the period of film formation depends primarily on the flow rate, the composition of the solution, the temperature, and the presence of additives. If the other variables remain constant, increasing the temperature decreases the amount of metal that is corroded during the formation of the protective coating and reduces the velocity effect.

5-4.3 Effect of solution flow rate.

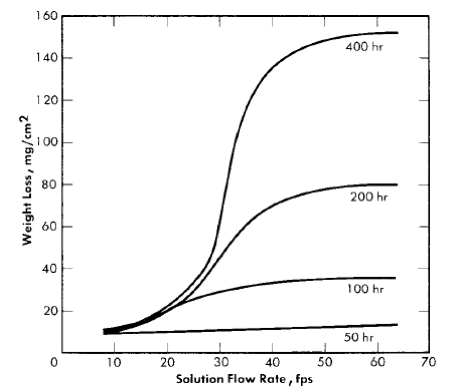

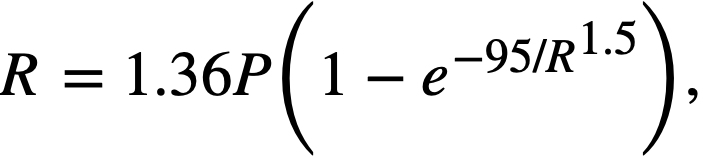

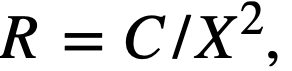

From room temperature to about 175°C the solution flow rate has essentially no effect on the corrosion rate of the stainless steel. However, at temperatures of 200°C and above, the corrosion rate is profoundly influenced by flow rate. Figure 5-11 shows typical results obtained using a tapered-channel specimen holder in a stainless steel loop. The data were obtained from a series of runs in which 0.17 m UO2SO4 was circulated at 250°C for various times. Since at low flow rates the corrosion rate depends on time, weight loss rather than corrosion rate is used as the ordinate.

Fig. 5-11. Corrosion of type-347 stainless steel in 0.17 m UO2SO4 at 250°C as a function of the flow rate.

At flow rates up to about 20 to 25 fps all weight losses were nearly the same regardless of exposure time. Between 25 and 35 fps weight losses increased sharply, and at still higher flow rates the weight loss of the specimens was proportional to the exposure time. An examination of the specimens revealed that up to about 20 fps the specimens were completely covered with a black, relatively heavy, tenacious scale which, after it formed, practically prevented further corrosion. In the region of 25 to 35 fps there were areas of the specimens that remained free of scale. At flow rates greater than 40 fps the specimens did not develop any visible scale, and upon removal from the holder the specimens had the appearance of severely etched steel.

Although the results presented in Fig. 5-11 are for only one concentration of uranyl sulfate, a similar velocity effect is observed at all uranyl-sulfate concentrations and at all temperatures above 200°C. The temperature of 200°C is in the middle of the transition region below which velocity is unimportant and above which a velocity effect is observed. Therefore, at 200°C a velocity effect is observed but is not well defined. Usually all specimens, even at the highest flow rate, develop a black coating which gives partial protection. In addition, the extent of the velocity effect is dependent on the exposure time.

The velocity below which a completely protective scale forms is defined as the critical velocity. The weight loss of stainless-steel specimens above this velocity increases linearly with time, and the corrosion rate is constant. Below the critical velocity the stainless steel corrodes initially at the same rate as at the high velocities, but the rate decreases as the protective coating forms and, generally, after about 100 hr very little, if any, corrosion occurs. In fact, some specimens have been exposed continuously at flow rates less than the critical velocity for periods of time as long as 20,000 hr and the amount of metal corroded was no greater than after 100 hr [29].

5 4.4 Effect of uranyl sulfate and sulfuric acid concentration.

All uranyl-sulfate solutions are acid, and the more concentrated the solution, the lower the pH as measured at room temperature. The acidity is further increased by adding sulfuric acid to dilute uranyl sulfate solutions to prevent hydrolytic precipitation of copper and uranium at high temperature.

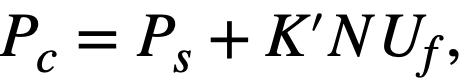

Generally, the higher the concentration of uranyl sulfate or free acid in solution, the greater the extent of metal dissolution during film formation below the critical velocity, the lower the critical velocity, and the higher the film-free corrosion rate above the critical velocity. Table 5-7 shows how the above three regions change with uranyl-sulfate concentrations at 250°C.

Table 5-7

The Corrosion of Type-347 Stainless Steel in Uranyl Sulfate Solutions at 250°C

| Concentration | Wt, loss | Critical | Corrosion rate |

| of UO2SO4, | at 10 fps, | velocity, | at 60 fps, |

| m | mg/cm2 | fps | Mpy |

|

|

|

|

| 0.02 | 1-2 | > 50 | ~ 10 |

| 0.11 | 2-3 | 25-30 | 190 |

| 0.17 | 12 | 20-25 | 190 |

| 0.43 | 20 | 10-20 | 400 |

| 0.84 | 37 | 10-20 | 680 |

| 1.3 | 50 | 10-20 | 1400 |

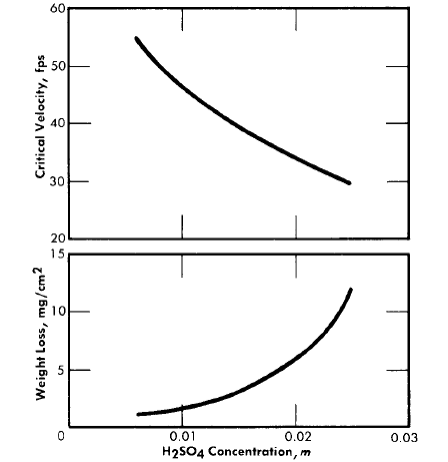

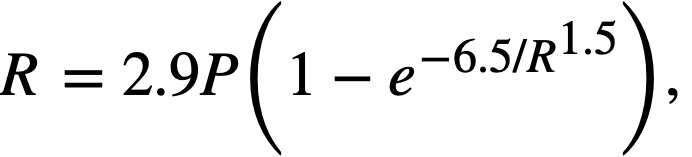

Fig. 5-12. The effect of sulfuric acid concentration on the critical velocity and on the extent of corrosion at low flow rates at 250°C. Solution composition: 0.04 m UO2SO4and 0.005 m CuSO4 .

Figure 5-12 shows the effect of sulfuric acid added to 0.04 m UO2SO4 containing 0.005 m CuSO4 , on the amount of metal dissolved during film formation and on the critical velocity of the system. The effect of adding sulfuric acid is qualitatively the same at all uranyl sulfate concentrations and at all temperatures above 200°C and produces a result similar to that of increasing the uranyl sulfate concentration. Thus it can be concluded that the acidity of the solution determines, at least in part, how much metal dissolves before a protective coating forms, and the critical velocity of the solution. It has been found that low concentrations of copper sulfate in uranyl sulfate solutions have no significant effect on the corrosion of type-347 stainless steel.

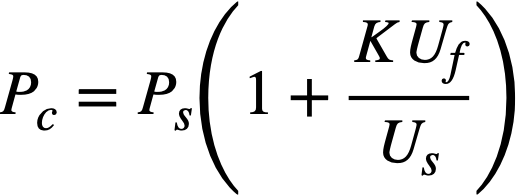

5-4.5 Temperature dependence of flow effects.

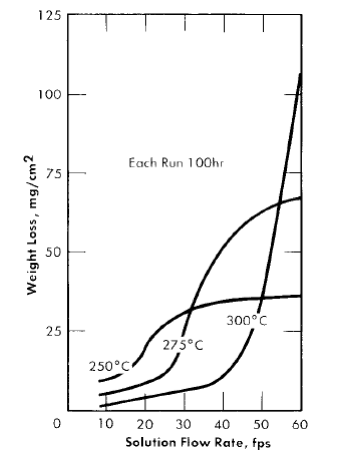

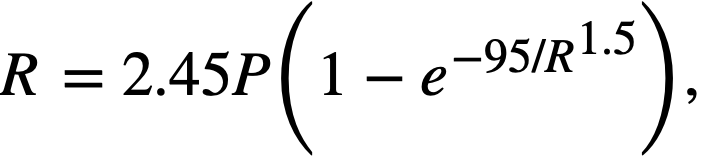

It has been stated that increasing the flow rate of the solution generally produces a detrimental effect on the corrosion of type-347 stainless steel. This effect is temperature-dependent, as shown in Fig. 5-13. Although the results are based on a 0.17 m UO2SO4 solution, an increase in temperature has a similar effect at all concentrations. With a given solution composition (i.e., constant uranyl sulfate and sulfuric acid concentrations), increasing the temperature decreases the amount of metal that dissolves during film formation, increases the critical velocity, and increases the film-free corrosion rate of the stainless steel. The reasons for these effects are discussed in Article 5 4 . 7 .

Fig. 5 13 . The corrosion of type -347 stainless steel in 0.17 m UO2SO4 at different temperatures.

5-4.6 Effect of corrosion inhibitors.

The number of substances that can be added to uranyl sulfate solutions to serve as corrosion inhibitors is limited for two reasons: (1) all organic inhibitors are oxidized to carbon dioxide in high-temperature oxygenated uranyl sulfate solutions, and (2) many inorganic compounds are insoluble in uranyl sulfate solutions. In spite of the second limitation, a number of inorganic salts have been added to uranyl sulfate solutions to determine their effectiveness in reducing the corrosion of type -347 stainless steel. Those substances that have been tested include: Li2SO4, Na2SO4, BeSO4, MgSO4, Ag2SO4, CuSO4, Cr2(SO4)3, NiSO4, FeSO4, MnSO4, Ce(SO4)2, [Ru(NO)]2(SO4)3, NaNO3, Na2SO4, Na2SiO3, NaBiO3, H2MoO4, H3SbO4, H7P(MoO4)12, As2O5, (UO2)3(PO4)2, NH4TcO4, and K2Cr2O7.

Of the compounds listed, only potassium dichromate and certain of the sulfate salts of the alkali and alkaline earth metals have been effective. Chromium(VI) was effective even at very low concentrations, whereas the sulfate salts had to be present in amounts nearly equal in molality to the uranyl sulfate.

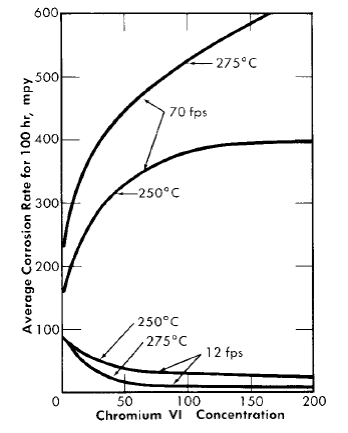

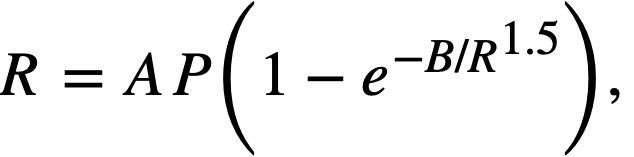

Fig. 5-14. The effect of Cr(VI) in 0.17 m UO2SO4 on the corrosion of type-347 stainless steel.

The addition of chromium(VI) to high-temperature uranyl sulfate solutions reduces the amount of metal corroded during film formation, greatly increases the critical velocity, but materially increases the corrosion rate of the stainless steel at flow rates in excess of the critical velocity. Results obtained using coupon-type corrosion specimens in a loop through which 0.17 m UO2SO4 was circulated at 250°C indicated that 200 ppm chromium(VI) increased the critical velocity from 20 to 25 fps to between 50 and 60 fps [30]. Other tests were carried out in which two pin-type specimens were exposed for 100 hr at flow rates both above and below the critical velocity in 0.17 m UO2SO4. The results are presented in Fig. 5-14. The corrosion rates at 70 fps are true rates which would not change on continued exposure; those at 12 fps are average rates for the 100-hr exposures and would decrease. Had the exposure been for 200 hr, the rates would have been approximately half those shown. It should be noted that as the film-free corrosion rate increased, the average corrosion rate at the low flow rate decreased.

It has been found that the presence of added sulfate salts in nearly equimolal concentration appreciably reduced the corrosion by concentrated uranyl sulfate solutions. The salts that have been studied the most are beryllium sulfate, lithium sulfate, and magnesium sulfate. The phase stability [31] of the above solutions has been reported, as have the corrosion results [32-34]. For example, the weight loss for a 200-hr exposure of stainless steel in 2.0 m UO2SO4 containing 2.0 m Li2SO4 at 200°C was only 5 mg/cm2 for velocities up to 60 fps. This may be compared with 100 mg/cm2 for exposure to a 1.3 m UO2SO4 solution under similar conditions. The effect of lithium sulfate was less pronounced at 25O°C and high velocities; at 250°C and 50 fps, weight losses were approximately 70 and 400 mg/cm2, respectively, for solutions of these same concentrations. For flow velocities less than 30 to 40 fps initial weight losses were found to be in the range of 5 to 15 mg/cm2 for eqiuimolal concentrations of uranyl sulfate and lithium sulfate up to 4.4 m and temperatures up to 350°C.

In dilute uranyl sulfate solutions the addition of sulfate salts also reduces the corrosion of stainless steel, but at temperatures of 250°C and higher the solutions are chemically unstable and complex hydrolytic precipitates form. At lower uranyl sulfate concentrations (0.04 to 0.17 m) the solutions demonstrating the greatest stability are those containing beryllium sulfate, and of the three sulfates most investigated, the least stable of the solutions were those with lithium sulfate. Sulfuric acid can be included in such solutions to prevent precipitation, but in so doing some of the effectiveness of the sulfate salt is lost. However, addition of both lithium sulfate and sulfuric acid to dilute uranyl sulfate solutions has been found to result in improved corrosion resistance of zirconium alloys on in-pile exposure [35].

5-4.7 Qualitative mechanism of the corrosion of stainless steel in uranyl-sulfate solutions.

Although any proposed mechanism for the corrosion of stainless steel in uranyl sulfate solutions at high temperatures must be considered qualitative, from a study of the effects of several variables on corrosion and from visual observation of high-temperature solutions sealed in quartz tubes, certain conclusions can be drawn and the over-all reaction processes determined.

The austenitic stainless steels and most other metals and alloys of practical importance in large-scale homogeneous reactors are thermodynamically unstable in aqueous solutions and depend on protective films for their corrosion resistance. Fortunately, when austenitic stainless steels are oxidized in high-temperature. uranyl sulfate solutions, the steel oxidizes uniformly so that no element (or elements) is leached preferentially from the alloy. However, not all the alloying elements contribute to film formation.

The oxidation and reduction processes of the corrosion reaction can be considered separately, with the oxidation reactions (considering only the major alloying elements) represented in the following manner:

Fe, Cr, Ni → Fe(II) + Cr(III) + Ni(II) + e-, (5-1)

Fe(II) → Fe(III) + e-. (5-2)

Both iron(II) and nickel(II) are soluble in uranyl sulfate solutions to an appreciable extent at high temperature, but if an oxidizing agent more powerful than uranyl ions is present, the reaction indicated by Eq. (5-2) takes place. [Manganese(II) also remains in solution.]

The half-reaction for the reduction can be any of the following, depending on the conditions:

O2 + 4H+ + 4e- → 2H2O. (5-3)

UO2(II) + 4H+ + 2e- → U(IV) + 2H2O. (5-4)

2H+ + 2e- → H2. (5-5)

In most concentrations of uranyl sulfate at temperatures greater than 200°C (and probably even at somewhat lower temperatures), iron (III), chromium(III), and uranium(IV) are present in solution only briefly before hydrolyzing in the following manner:

2Fe(III) + 3H2O → Fe2O3 + 6H+, (5-6)

2Cr(III) + 3H2O → Cr2O3 + 6H+, (5-7)

2UO2(II) + U(IV) + 4H2O → U3O8 + 8H+. (5-8)

In a system containing oxygen the total reduction process is represented by Eq. (5-3), although it is highly probable that other ions enter into the reaction mechanism. Only in the absence of oxygen is either U3O8 or hydrogen found in the system.

If we examine the equations as written, it is apparent that the over-all corrosion of stainless steel in uranyl sulfate solutions containing oxygen can be represented by the sum of Eqs. (5-1), (5-2), (5-3), (5-G), and (5-7), taking into account the percentage of each element in the alloy. From the over-all reaction it can be seen that the amount of oxygen consumed can be used to measure the quantity of stainless steel corroded. In addition, since the nickel originating from the corrosion process remains soluble, the total quantity of stainless steel oxidized can be determined from a knowledge of the nickel content of the uranyl sulfate solution. Measurements of nickel content and oxygen consumption have been found to agree well with weight loss for determining total corrosion. Since the nickel remains soluble and replaces hydrogen ions, the pH of the solution slowly increases as corrosion proceeds.

In a system depleted in oxygen, uranium is reduced and precipitated as U 3 O 8 , producing hydrogen ions while ferrous ions remain soluble. Consequently, a pH measurement gives an indirect measure of the presence or absence of oxygen in the system. Similarly, the presence of ferrous ions even in very small amounts indicates a deficiency of oxygen and that uranium is beginning to precipitate from the solution.

Once an anhydrous protective coating has formed on the surface of the stainless steel, the steel corrodes at an extremely slow rate. However, since the oxide coatings are thick, it is probable that they are under stress, and fine cracks or imperfections form. When the film-free metal at the base of the crack is exposed to the solution, the metal again corrodes actively until the corrosion products repair the crack. During extended periods of testing, this process is probably repeated many times over the surface of the specimen, with the net observable result being a uniform attack of the specimen.

In the proposed mechanism of film formation, both iron and chromium form ions before undergoing hydrolysis and crystallization on the surface of the stainless steel. This mechanism can account for the existence of a critical velocity, since ions and hydrolyzed particles can diffuse into the circulating stream before forming the film if the diffusion layer is too thin. Since the diffusion-layer thickness depends on the flow rate or turbulence, the process of film formation is, in essence, in competition with diffusion and turbulence. The critical velocity, then, is that flow rate (or turbulence) at which the diffusion layer is reduced to such an extent that most of the corrosion products get into the main circulating stream before they can form on the surface of the stainless steel. Under conditions where the rates of dissolution and hydrolysis are fast, the critical velocity would be expected to be relatively high.

It has been mentioned that solutions of uranyl sulfate are acid and that the higher the uranyl sulfate concentration, the lower the pH of the solution. Also, data have been presented to show that the higher the uranium concentration, the greater the corrosion rate of film-free stainless steel. These two factors essentially work against each other with regard to film formation; that is, a high corrosion rate would introduce relatively large concentrations of corrosion products into the solution in the immediate region of the stainless steel surface, a factor which should facilitate the formation of a protective film. But even though more corrosion products are present, the hydrogen ion concentration is also substantially greater. Since hydrolysis reactions are very dependent on the hydrogen ion concentration, the rate of film formation is actually retarded, so that the net result is the dissolution of more stainless steel at high uranyl sulfate concentrations than at lower concentrations before a protective film is formed. Because the process of film formation is slower the higher the uranyl sulfate concentration, the critical velocity is also lower the higher the uranyl sulfate concentration.

Since the presence of sulfuric acid in uranyl sulfate solutions also decreases the rate of hydrolysis, the addition of sulfuric acid has about the same effect as increasing the uranyl sulfate concentration.

The effect of temperature on the formation of a protective coating can be accounted for by considering the effect of temperature on the rate at which the corrosion products are formed and on their rates of hydrolysis. Increasing the temperature increases the rate at which corrosion products enter the solution and also the rate of hydrolysis, with the net result that films form faster and that the critical velocity is increased. Because the initial corrosion rate and the rate of precipitation are fast, it would be expected that the crystallite size of the oxide would be smaller the higher the temperature of formation and this has been found to be true. Apparently a compact layer of small crystals forms a more protective and adherent coating than one composed of large crystals.

It is probable, though seemingly paradoxical, that chromium (VI) serves as a corrosion inhibitor, at least under certain conditions, because it accelerates the film-free corrosion rate of stainless steel. In this respect, the effect of adding chromium(VI) to uranyl sulfate solutions is similar to that of increasing the temperature. Because of the increased corrosion rate, large quantities of corrosion products are formed near the surface of the stainless steel, and hence the solubility limit of the oxides is exceeded rapidly and many small crystals form on the surface of the stainless steel. Even though the rate of hydrolysis is not increased as it is at the higher temperatures, the diffusion rate is slower, so that the corrosion products are in the vicinity of the stainless steel longer. Because the film forms faster, the critical velocity is higher in the presence of chromium(VI) than in its absence, other variables remaining the same.

The reason why the addition of relatively large quantities of inert sulfate salts to uranyl sulfate solutions reduces the corrosiveness of the resulting solutions is not known, but may be due to one of a number of factors, such as the formation of stable complexes, reduction of acidity, changes in oxidizing power, increased viscosity and density, or changes in colloidal properties of the oxide.

5-4.8 Radiation effects.35

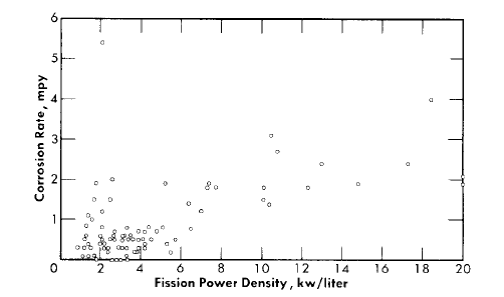

The effect of radiation on the corrosion behavior of stainless steel is important in relation to the use of this material in construction of the fuel-circulating system and reactor pressure vessel of a homogeneous reactor. The radiation levels thus encountered, however, are considerably less than for the zirconium core tank. For example, the fission power density of the solution in contact with the stainless steel in the HRE-2 will not exceed 1 kw/liter for operation at 10 Mw, and in a large-scale two-region breeder or single-region burner reactor would not be more than 5 kw/liter. These values may be compared with fission power densities of up to 50 kw/liter at the surface of the zirconium core tank.

The corrosion behavior of type-347 stainless steel in uranyl-sulfate solutions under irradiation at high temperature has been studied in a number of in-pile loop and in-pile autoclave experiments. A few scouting type experiments of the effect of van de Graaff electrons on steel corrosion have also been carried out. Although most of the information for the radiation effect on steel has its source in these experiments (in particular, the loop experiments), information of a general nature has been derived from the performance of the stainless steel portion of the HRE-1.

With loop experiments, specimens were located in the core portion of the loop and in portions of the loop external to the core and out of the high-flux region [30], as shown in Fig. 5-6 (Article 5-2.2). Coupons and other specimens exposed in these latter positions are designated ^'in-line specimens.’^ Specimen preparation, in general, comprised only cleaning after machining. However, prior to radiation exposure, each experimental system, including the specimens, was exposed first to water, with or without oxygen, and then to oxygenated uranyl sulfate solution at a temperature near the test temperature [37]. Corrosion attack of a specimen was determined from weight-loss measurements, visual inspection, and metallo-graphic examination. The course of corrosion of the system during exposure in both loops and autoclaves was followed by measuring the rate of oxygen consumption. The approximate operating conditions and other experimental information for the loop tests are shown in Table 5-9 (Article 5-5.3). All the loops contained steel specimens except those otherwise indicated. Experiment L-2-14 contained only a few steel coupons. A detailed description of methods and procedures employed with the in-pile tests is presented in Article 5-5.3.

The behavior of steel under exposure to a solution in which fissioning is occurring in the immediate neighborhood of the surface appears to change appreciably with changes in experimental conditions. No comprehensive picture of the behavior is available as yet, and only the general features of the experimental results can be reported. Pits of 1 to 2 mils in depth, which appear to spread laterally and merge (with increasing attack), are usually found on the surfaces of specimens which have suffered appreciable attack [38]. After the merging of pits, the attack appears to proceed fairly uniformly over a surface.

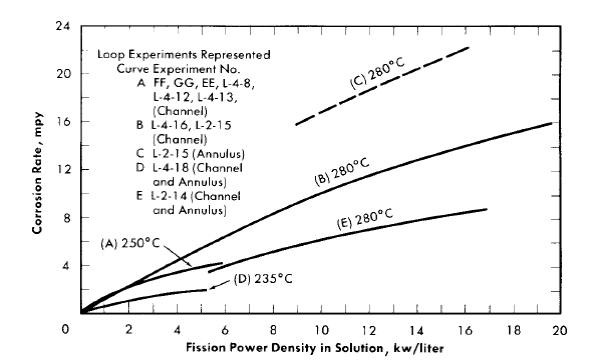

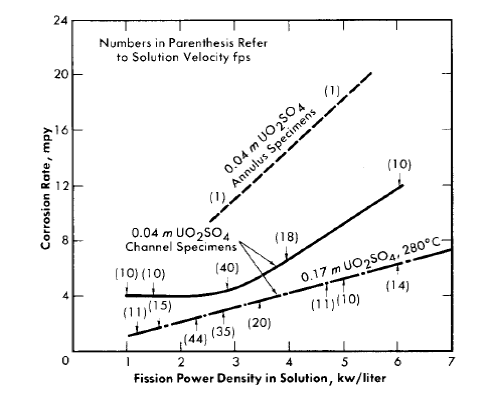

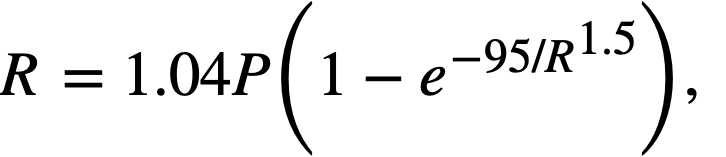

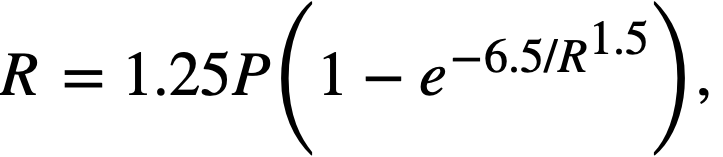

Average corrosion rates which have been determined for core specimens in 0.17 m UO2SO4 solution plus varying amounts of H2SO4 and CuSO4 varied between 0.1 and >180 mpy for solution power densities up to 5 kw/liter and for solution velocities up to 45 fps [39]. These rate values for specimens and the other rates quoted below are based on exposed specimen areas and radiation time.

With the exception of the results of two experiments, the rates observed at power densities below 2 kw/liter were less than 2 mpy. In one of the experiments, L-4-8, for which the results are an exception of this generalization, a specimen exposed to a solution power density of about 2 kw/liter and an average solution velocity of about 40 fps exhibited a rate of 40 mpy. The pattern of the results in this case indicated that the high solution velocity was, in part, responsible for the high rate. In the other experiment, DD, rates varying from 2.5 to 57 mpy at solution power densities from 0.3 to 1.7 kw/liter and solution velocities from 10 to 40 fps were observed. This experiment was the first of the series of loop experiments. The higher rates in this loop may have been associated with the exceptional solution conditions. Only a small amount of excess acid was added initially, and it was estimated that this excess was consumed in the solution of nickel produced in corrosion during the course of the experiment. This solution condition was not repeated in subsequent experiments [40].

No significant acceleration of corrosion has been observed with specimens exposed at in-line positions in the loops; that is, at positions in which the sample is not exposed to neutrons but is exposed to solution which has passed through the core. Average corrosion rates for in-line specimens were less than 2.3 mpy for all cases considered. These in-line specimens were exposed to solution velocities in the range of 10 to 40 fps, but no significant effect of velocity on the corrosion rate was observed [41]. However, in one experiment, L-4-12, a single pit was observed in the surface of the recessed shoulder of the volute inlet of the pump, a high-velocity region [42]. It should be noted that the rates mentioned are based on the loss in weight of a specimen during exposure as measured after a cathodic defilming treatment. The oxide is not always removed quantitatively in this treatment. Weight gains were frequently observed for in-line specimens, and in these cases the rate of attack was assumed to be zero.

The results of the experiments with van de Graaff electrons have not shown any significant effect of electron irradiation on the corrosion of type-347 stainless steel by uranyl sulfate solutions at the high temperatures. One of these experiments, carried out in a type-347, stainless steel thermal siphon loop, was with an oxygenated 0.17 mUO2SO4 solution at 250°C. The intensity of electron irradiation was such that the estimated power density from absorption of electron energy in solution adjacent to the specimen was 20 to 30 kw/liter. Two exposures, each of 50-hr duration, were made, and no significant difference was observed between the attack of irradiated and nonirradiated specimens [43]. The other experiment was conducted in a titanium thermal loop with an oxygenated solution, 0.04 m UO2SO4, 0.025 m H2SO4, and 0.01m CuSO4 at 280°C. The estimated power density due to absorption of electron energy adjacent to the specimen was about 60 kw/liter. Again no significant difference between the attack of irradiated and nonirradiated specimens was noted in a 50-hr exposure [44].

It has been suggested that chemical changes in solution due to fissioning and/or the radiation from fission-product decay, both of which would be proportional to the total fission power averaged over the total solution volume of the high-pressure system, might have an adverse effect on the behavior of the stainless steel located in the regions external to the core. In loop experiments at average power densities up to 1.5 kw/liter, no such effect was apparent. The only available information on the corrosion of type-347 stainless steel at higher average power densities is that from the HRE-1. In this case the maximum average power density was about 14 kw/liter, and the over-all stainless steel corrosion rates (including the core tank) were 6 to 8 mpy as judged from data for total nickel in solution [45].36

The influences of some of the variables on the corrosion behavior of stainless steel under exposure to a fissioning solution, as indicated by the results to date, are listed and summarized as follows:

Fission power density. Corrosion is accelerated by exposure to fissioning uranyl sulfate solution, and the degree of acceleration increases with increasing fission power density in solution. In several experiments, reasonably good proportionality was found between the fission power density to which a specimen was exposed and the logarithm of the average corrosion rate of the specimen during exposure.

Excess H2SO4. One interpretation of some of the results is that the optimum concentration of excess H2SO4 is between 0.01 and 0.02 m, and that concentrations above and below these limits may have an adverse effect on in-pile corrosion.

Velocity of solution at specimen. There is some evidence that the in-pile rate increases with increasing solution velocity.

Radiolytic-gas pressure. A possible interpretation of some of the results is that the in-pile rate is diminished as the concentration of radiolytic gas in solution increases.

Galvanic effects. The possibility of galvanic effects on corrosion under some in-pile conditions has not been ruled out.

Temperature. In general, the attack observed at 250°C was greater and less predictable than that observed at 280°C.

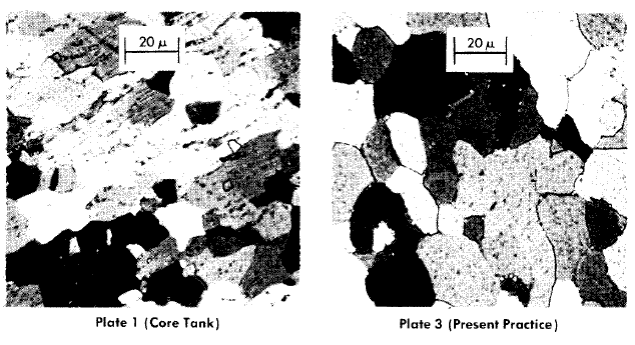

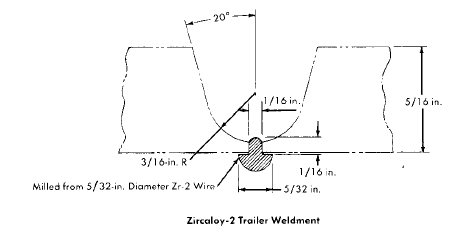

5 5. Radiation-Induced Corrosion of Zircaloy-2 and Zirconium37

5-5.1 Introduction.

Crystal-bar zirconium and Zircaloy-2 have been tested at elevated temperatures in uranyl sulfate solutions under dynamic and static conditions in the absence and in the presence of radiation. Both the metal and alloy are very corrosion resistant in the absence of radiation. However, under exposure to nuclear radiations, particularly those from fissioning uranium solution, corrosion rates may be appreciably greater than those observed out-of-radiation. Although most of this section will be concerned with the in-pile studies, some of the out-of-pile tests will also be described.

5-5.2 Corrosion of Zircaloy-2 and zirconium in uranyl sulfate solutions in the absence of radiation.

Most of the radiation-free experiments were of the type in which specimens of the metal to be tested were exposed in autoclaves or loops constructed of stainless steel or titanium. The uranyl sulfate solutions were oxygenated and usually contained excess H2SO4. CuSO4 was also added in some tests. Cleaned, as-machined specimens were employed. Under exposure to the uranyl sulfate solutions at high temperature, the specimens generally formed a black, tightly adhering film within 100 hr. These films could not be removed without damage to the metal, and the amount of corrosion was estimated from the weight of a specimen together with the oxide.

Zirconium and Zircaloy-2 specimens exposed in solutions circulating in stainless steel systems collected some of the stainless steel corrosion products (iron and chromium oxides) in an outer layer of scale. This outer layer could be removed partially by a cathodic defilming operation. A sodium hydride bath treatment was required for complete removal. Table 5-8 lists values for long-term average corrosion rates observed in a solution 0.04 m in UO2SO4, 0.02 m in H2SO4, and 0.005 m in CuSO4 at 200, 250, and 300°C.

Table 5-8

Long-Term Corrosion Rates of Zirconium and Zircaloy-2 in Uranyl Sulfate Solutions

| Material | Corrosion rate, mpy | ||

| 200°C | 250°C | 300°C | |

| Crystal-bar zirconium | < 0.01 | < 0.01 | 0.13 |

| Zircaloy-S | < 0.01 | < 0.01 | 0.04 |

These rate values were calculated from the decrease in weight of de-filmed specimens as measured following an initial exposure period of several days. Other tests gave similar results at uranyl sulfate concentrations from 0.02 to 1.3 m. No evidence for appreciable acceleration of attack during exposure was observed during tests of up to 20,000 hr.

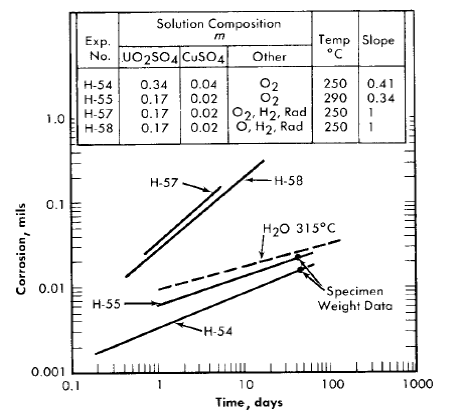

A few experiments with Zircaloy-2 were carried out in autoclaves similar to the in-pile type [46] described in Article 5-2.2. In these experiments, the autoclave was constructed of Zircaloy-2 and was charged with the test solution, oxygen gas, and specimens. The test surfaces were as-machined and cleaned. Corrosion during exposure was determined by measuring the rate of oxygen loss within the system. The results of two of these experiments, H-54 and H-55, are shown graphically in Fig. 5-15, where the thickness of the layer of metal which was converted to oxide or removed by oxidation is plotted on a log-log plot versus the exposure time.

Data reported by Thomas [47] on the behavior of Zircaloy-2 in deaerated water at temperatures of 290 and 315°C, when converted into values for the thickness of the layer of oxidized metal, are similar to those for H-54 and H-55. The water data at 315°C are illustrated in Fig. 5-15 by the dotted line. From these results, it appears that the out-of-pile behavior of Zircaloy-2 in oxygenated uranyl sulfate solutions is similar to that in deaerated water in the temperature region investigated.

5-5.3 Methods and procedures employed with in-pile tests.

In-pile investigations were carried out with autoclaves and loops (described in Article 5-2.2). A majority of the autoclave experiments and all the loop experiments were conducted in the Low Intensity Test Reactor at ORNL. The maximum thermal-neutron flux available for these experiments was about 2 x 1013 neutrons /(cm2)(sec).

For most experiments, the autoclave and the corrosion specimens were constructed of the metal to be studied. The autoclave was partly filled with the solution to be tested, pressurized with oxygen, and stirred by rocking. Measurements of the oxygen pressure in the system during exposure provided information regarding the course of corrosion.

Most of the in-pile loops were constructed of type-347 stainless steel; however, in one experiment the loop was of titanium, and in another the core portion only was of titanium. Corrosion specimens were placed in the core and in a portion of the loop which is outside the region of appreciable neutron flux. The specimens in the latter position were usually duplicates of the core specimens. The over-all corrosion behavior during exposure was followed by measuring the rate of oxygen consumption within the system, and by chemical analysis of solution samples which were withdrawn from time to time. Specimen examination included visual and metallographic inspection, and weight measurements. The exposure conditions and composition of test solution which prevailed for each of the in-pile loop experiments are listed in Table 6-9. Unless otherwise noted, all tests were run with a light-water solution of 0.17 m UO2SO4 in a type-347 stainless steel loop. CUSO 4 concentrations from 0.008m to 0.07 m were employed. Oxygen pressures ranged from highs of 140 to 195 psi to lows of 35 to 90 psi. Pressurizer temperatures were normally 15 to 30°C higher than the temperature of the main stream.

Table 5-9

Approximate Operating Conditions for in-Pile Loop Experiments

| Loop number | Excess H2SO4 | Estimated radiolytic gas, main stream (cc/liter, STP) |

Temp. main stream, °C

|

Fission power density | Time | |||

| Range, m |

Mean, m |

Range adjacent to core specimens, kw/liter |

Average in total loop solution, kw/liter |

Total operating time at temperature, |

Time of irradiation at full power, hr |

|||

| DD (a) | 0.008-0 | 0.003 | 120 | 250 | 1. 7-0.3 | 0.50 | 550 | 280 |

| FF (f) | .021-0040 | .028 | 170 | 250 | 3.7-0.7 | .55 | 816 | 467 |

| GG (f) | .015- 043 | .026 | 220 | 250 | 4.8-1.3 | .75 | 1169 | 897 |

| BE | .004-008 | .006 | 170 | 250 | 5.7-1.0 | .48 | 757 | 537 |

| L-4-8 | .017- 044 | .023 | 170 | 250 | 5.1-0.7 | .55 | 1729 | 1459 |

| L-4-11 | .008-040 | .022 | 220 | 250 | 7.0-1.3 | .62 | 1203 | 725 |

| 1.-4-12 (d) | .027- 044 | .031 | 180 | 250 | 4.8-0.9 | .67 | 2173 | 1462 |

| L-2-10 (b) | .014-021 | .018 | 170 | 280 | 4.2-0.8 | .41 | 1869 | 1255 |

| L-4-13 (c) | .010- 021 | .015 | 280 | 250 | 6.3-1.1 | .55 | 1212 | 787 |

| 1.-2-15 | .027-030 | .028 | 370 | 278 | 19.8-4.6 | 1. 70 | 831 | 544 |

| L-4-16 | .022- 026 | .024 | 110 | 280 | .'5.7-1.3 | .45 | 1200 | 775 |

| L-2-14 (e-g) | .37-42 | .40 | 50 | 280 | 20.8-4.3 | 1.80 | 1034 | 510 |

| L-2-17 (h) | .024- 028 | .024 | 140 | 300 | 6.7-1.4 | .48 | 1333 | 875 |

| L-4-18 (c) | .018-020 | .019 | 200 | 235 | 5.2-1.1 | .52 | 1021 | 642 |

Fig. 5-15. Comparison of Zircaloy-2 corrosion in various environments.

The solution compositions for a majority of the autoclave experiments are summarized in Table 5-10. In the usual experiment, the fission power density was 20 w/ml or less. In a few exceptional autoclave experiments, power densities considerably greater than 20 w/ml were achieved [48]. Operating temperatures ranged from 225 to 300°C, with most experiments at 250 or 280°C.

Table 5-10

Summary of Solution Composition for Autoclave Radiation Corrosion Experiments with Zircaloy-2

| Component | Concentration |

| U02S04 (90% enriched uranium) | 0.17m |

| CUS04 | 0.01-0.04 m |

| H2SO4 | 0-0.04 m |

| Excess 02 | 900-20 psi |

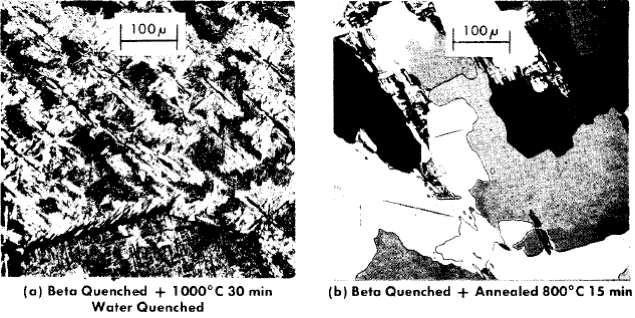

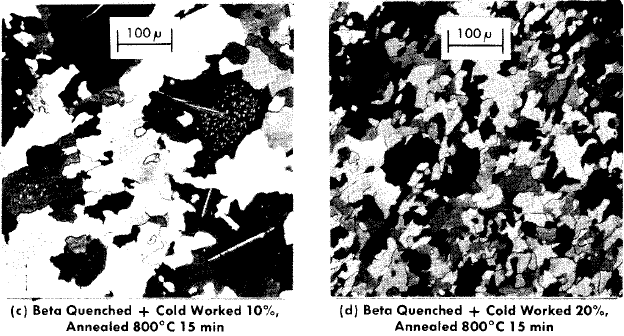

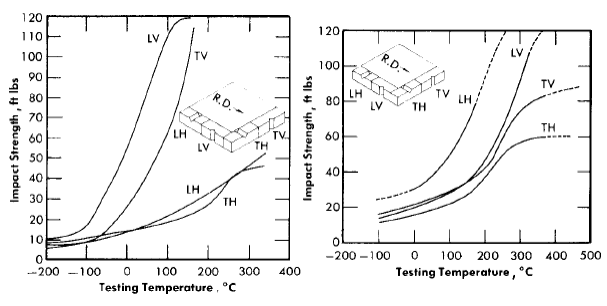

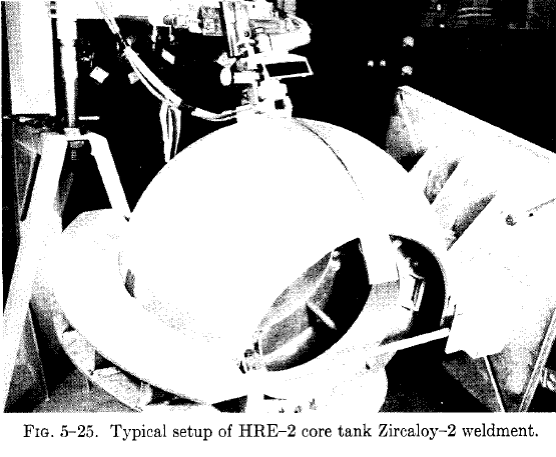

| Radiolytic gas | 0-500 psi |