CHAPTER 7

DESIGN AND CONSTRUCTION OF EXPERIMENTAL HOMOGENEOUS REACTORS53

7-1. Introduction

7-1.1 Need for reactor construction experience.

The power reactor development program in the United States is characterized by the construction of a series of experimental reactors which, it is hoped, will lead for each reactor type to an economical full-scale power plant. Outstanding examples of this approach are afforded by the pressurized water reactor and boiling water reactor systems. The development of pressurized water reactors started with the Materials Testing Reactor, followed in turn by the Sub-marine Thermal Reactor (Mark I), the Nautilus Reactor (Mark II), and the Army Package Power Reactor. Experience obtained from the construction of these reactors was applied to the full-scale plants built by the Westinghouse Electric Company (Shipping-port and Yankee Atomic Electric Plants) and Babcock & Wilcox Company (Consolidated Edison Plant).

Although many have argued that the shortest route to economic power will be achieved by eliminating the intermediate-scale plants, most experts believe that eliminating these plants would be more costly in the long run. To quote from a speech by Dr. A. M. Weinberg [1], while discussing large-scale reactor projects: "The reactor experiment-a relatively small-scale reactor embodying some, 'but not all, the essential features of a full-scale reactor-has become an accepted developmental device for reactor technology."

An alternative to the actual construction of experimental nuclear reactors has been proposed which consists of the development of reactor systems and components in nonnuclear engineering test facilities, zero-power critical experiments, and the testing of fuel elements and coolants in in-pile loops. This approach, although used successfully in the development of various solid-fuel coolant systems, is not completely applicable to circulating-fuel reactors because of the difficulty of simulating actual reactor operating conditions in such experiments. In in-pile loops, for example, the ratio of the volume of the piping system to the volume of the reacting zone is never quite the same as in a reactor, making it impossible to duplicate simultaneously the conditions of fuel concentration, enrichment, and power density. In cases where these variables are important, the in-pile loops can at best provide information of an exploratory nature which must be verified in an operating fluid-fuel reactor.

A second aspect of circulating-fuel reactors, which precludes relying solely on engineering tests and in-pile loops, is the close interrelation of the nuclear behavior and the operational characteristics of the fuel circulation system, which can be determined only through construction and operation of a reactor. Other aspects of reactor design that can be best determined in an operating homogeneous reactor are continuous removal of fission products produced in the nuclear reaction and remote decontamination and maintenance of reactor equipment and piping.

7-1.2 Sequence of experimental reactors.

It is obvious from the fore-going that the construction of a sequence of experimental reactors has been an important factor in the development of homogeneous reactors. In this sequence, which started with non power research reactors, seven such reactors have been built (not including duplicates of the water boilers). These are the Low Power Water Boiler (LOPO), the High Power Water Boiler (HYPO), the Super Power Water Boiler (SUPO), the Homogeneous Reactor Experiment (HRE-l), the Homogeneous Reactor Test (HRE-2), and the Los Alamos Power Reactor Experiments (LAPRE-l and -2). In the sections of this chapter which follow, these reactors are described in detail, and their design, construction, and operating characteristics are compared. Their construction covers the regime of homogeneous reactor technology involving the feasibility of relatively small reactors fueled with aqueous solutions of uranium. Since their construction and operation does not include systems fueled with aqueous suspensions of thorium oxide and/or uranium oxides necessary for the development of full-scale homogeneous breeders or converters, additional experimental reactors will undoubtedly be built.

7-2. Water Boilers54

7-2.1 Description of the LOPO, HYPO, and SUPO [2-4].

Interest in homogeneous reactors fueled with a solution of an enriched-uranium salt was initiated at the Los Alamos Scientific Laboratory in 1943 through an attempt to find a chain-reacting system using a minimum of enriched fuel. The first of a sequence of such reactors, known as LOPO (for low power), went critical at Los Alamos in May 1954 with 565 grams of U235 as uranyl sulfate. The uranium, containing 14.5% U235, was dissolved in approximately 13 liters of ordinary water contained in a type-347 stainless steel sphere 1 ft in diameter and 1/32 in. in wall thickness. The sphere was surrounded by beryllium oxide as reflector in order to minimize the critical mass of the U235. The lack of a shield and cooling system limited the heat power level of LOPO to 50 milliwatts. A cross-sectional drawing of the LOPO is shown in Fig. 7-1.

Following successful low-power operation of the LOPO, the reactor was provided with a thicker sphere (1/16 in.), integral cooling coils, and a shield to permit operation at 6 kw. Also, part of the beryllium oxide reflector was replaced by a graphite thermal column, and holes through the shield and reflector were provided for experiments. The critical mass of the modified reactor was 808 grams of U235 as uranyl nitrate at 14.0% enrichment, contained in 13.65 liters of solution. The change from uranyl sulfate to nitrate was made because an extraction method for the removal of fission products was known only for the latter solution at that time. The modified reactor, called HYPO (high power), went critical in December 1944 and operated at a normal power of 5.5 kw, producing an average thermal-neutron flux of 1011 neutrons/(cm2)(sec). The temperature of the solution during operation reached 175°F with cooling water (50 gal /hr) at 46°F.

Since higher neutron fluxes were desired, as well as more research facilities than available from HYPO, the reactor was further modified and renamed SUPO (super power water boiler).

The modifications were made in two parts. The first phase, begun in April 1949 and completed in February 1950, improved the experimental facilities and increased the neutron flux. The second phase, begun in October 1950 and completed in March 1951, increased the thermal neutron irradiation facilities, improved the reactor. operation, and removed the explosive hazard in the exhaust gases.

The first group of alterations consisted of the following:

(1) The space around the reactor was increased by enlarging the building so that experiments could be carried out on all four sides instead of only two.

(2) The construction of a second thermal column was made possible by eliminating a removable portion of the reactor shield. This made available a neutron beam and irradiation facilities on a previously unused face of the reactor.

(3) The entire spherical core assembly was replaced as follows:

(a) Three 20-ft-Iong, 1/4-in.-OD, 0.035-in.-wall-thickness stainless steel tubes replaced the former single cooling coil. This increased the operating power level from 5.5 kw to a maximum of 45 kw.

(b) A new removable level indicator and exit gas unit was installed in the sphere stack tube. The stack tube itself was made more accessible for future modifications.

(c) External joints were not welded, but unions of flare fittings were used to simplify the removal of the sphere or permit pipe replacements.

FIG. 7-1. Cross section of LOPO, the first aqueous solution reactor.

(d) An additional experimental hole was run completely through the reactor tangent to the sphere. This 17/16-in.-ID tube supplemented the l-in.-ID "glory hole" running through the sphere.

(4) The beryllium portion of the reflector was replaced by graphite. The all-graphite reflector gave a more rapid and complete shutdown of the reactor and eliminated the variable starting source produced by the (γ, n) reaction on beryllium. A 200-millicurie RaBe source placed in the reflector was used as a startup neutron source.

(5) Two additional vertical control rods were added which moved into the sphere in re-entrant thimbles. These consisted of about 120 grams of sintered BIO in the form of 9/16-in. rods about 18 in. long. These rods gave the additional control required by the change to an all-graphite reflector. Previously observed shadow effects were eliminated by the internal position of the rods and by the location of the control chambers under the reactor.

(6) The reactor solution was changed from 15% U235-enriched uranyl nitrate to one of 88.7% enrichment. This made possible the continued use of a low uranium concentration in the solution with the poorer all-graphite reflector. The gas evolution produced by nitric acid decomposition was greatly reduced, due to the lower total nitrogen content.

(7) The entire inner reactor shield was improved to permit higher power operation with a low neutron leakage and also to increase the neutron – to – gamma - ray intensity in the thermal columns. Cadmium was replaced by B4C paraffin and additional steel shielding was added.

After operating the reactor with the above modifications for about 10,000 kwh at a power of 30 kw, the following (second group) alterations were made:

(1) The original south thermal column was completely rebuilt, with improved shielding to provide many more irradiation facilities.

(2) A recombination system was constructed to handle the off-gases from the reactor. The use of a closed circulating gas system with a catalyst chamber of platinized alumina removed any explosive hazard in the exhaust gases due to the presence of hydrogen and oxygen. The operating characteristics of the reactor were greatly improved by returning directly back to the reactor as water all but a very small fraction of the gases produced.

(3) A shielded solution-handling system was constructed to simplify the procedure of routine solution analysis and for the removal or change of the entire reactor solution.

The average neutron flux in the SUPO during operation at 45 kw is about 1.1 x 1012 neutrons/(cm2) (sec), and the peak thermal flux (in the "glory hole") is 1.7 x 1012 neutrons/'(cm2) (sec). Estimated values for the maximum intermediate and fast fluxes at 45 kw are 2.8 and 1.9 x 1012 neutrons /(cm2) (sec), respectively. Calculations made from fast beams emerging from the north thermal column at this same power level gave the following fast-flux values above 1 Mev in units of neutrons/(cm2)(sec): (1) at sphere surface, 1.1 x 1012; (2) at bismuth column, 7 x 1010; and (3) at a graphite face 1 ft in front of the bismuth column, 2 x 109.

The production of hydrogen plus oxygen due to radiation decomposition amounts to approximately 20 liters/min during operation of the reactor at 45 kw. These gases leave the reactor core and pass through a reflux con-denser which removes much of the water vapor and then through a stainless steel-wool trap for final moisture removal. A blower feeds the gas into one of two interchangeable catalyst chambers containing platinized alumina pellets. These chambers, operating at 370 to 470°C, recombine the hydrogen and oxygen, and the gas leaving the catalyst contains the water vapor formed. A second condenser reduces the temperature of the exit gas to that entering the catalyst chamber. A total of 100 liters/min of gas is circulated continuously in the closed gas system at pressures slightly above atmospheric, and the hydrogen concentration is kept below the detonation limit at all points of the system. Excess pressures produced in the gas system can be bled to the atmosphere through a 150-ft-high exhaust stack.

The characteristics of LOPO, HYPO, SUPO, and the North Carolina State College Water Boilers are summarized in Table 7-1.

Table 7-1

Design Characteristics Of Water Boilers

|

LOPO |

HYPO | SUPO | NCSR [5] |

| Power level, kw | 5 X 10-5 | 5.6 | 45 | 10 |

|

|

|

|

|

| Solution (in H2O) | UO2S04 | UO2(NO3)2 | UO2(NO3)2 | UOzS04 |

|

|

|

|

|

| U235 wt., grams | 565 | 870 | 870 | 848 |

|

|

|

|

|

| Solution volume, liters | 13 | 13.65 | 13.65 | 15 |

|

|

|

|

|

| Enrichment, % | 14.6 | 14.0 | 88.7 | 90 |

|

|

|

|

|

| Maximum thermal- neutron flux | 3 X 106 | 2.8 X 1011 | 1.7 X 1012 | 5 X 1011 |

|

|

|

|

|

| Reflector material | BeO | Be and graphite | Graphite | Graphite |

|

|

|

|

|

| Coolant flow rate gal/hr | None | 50 | 180 | 240 |

|

|

|

|

|

| Solution temperature, ºC | 39 | 85 | 85 | 80 |

|

|

|

|

|

| Experimental facilities | None | 1 thermal column | 2 thermal columns ("glory hole” and tangential hole) | 1 thermal column 12 exposure port |

7-2.2 Kinetic experiments in water boilers.

In August 1953, experiments were performed on the SUPO by a group of scientists from the Oak Ridge National Laboratory and Los Alamos [6,7] to determine the degree to which a boiling (and nonboiling) homogeneous reactor automatically compensates for suddenly imposed supercritical conditions. Previous boiling experiments in 1951, unreported in the open literature [8], had indicated the stability of SUPO under steady-state boiling conditions; however, there remained considerable doubt as to the adaptability of a reactor of this type to a sudden introduction of excess reactivity such as might occur with a sudden increase in pressure above the reactor. The tests were performed by suddenly ejecting a neutron poison, consisting of an aluminum rod containing boron carbide at its tip, and simultaneously measuring the neutron flux level with high-speed recorders connected to a boron-coated ionization chamber located in the graphite reflector. The amount of reactivity introduced was determined by the position of a calibrated control rod. Although the experiments were interrupted by frequent accidental scrams, caused by the unsuitability of SUPO to boiling at high solution levels in the sphere, the results indicated that both boiling and non boiling solution reactors are capable of absorbing reactivity increases of at least 0.4% keff added in about 0.1 sec. In both boiling and nonboiling cases, the reactor power was self-regulating, but excursions were terminated more rapidly under boiling conditions. The average lifetime of prompt neutrons in the reactor was calculated from the initial prompt rise in the neutron flux and found to be about 1.7 X 10-4 sec. Following a reactivity addition, the initial rate of reactivity decrease (0.2 sec after start) was greater than about five times the rate which could be attributed to core-temperature rise and the associated negative temperature coefficient (0.024% keff/ºC). As the gas bubbles left the core region, reactivity decrease due to core-temperature rise increased in relative importance.

More recent experiments with the Kinetic Experiment for Water Boilers (KEWB-1), operated by Atomics International for the U. S. Atomic Energy Commission [9], have verified the self-controlling features of a solution-type reactor. It was found that automatic shutdown due to the temperature increase and formation of gas bubbles in the reactor fuel solution occurs under all abnormal operating conditions tested.

7-2.3 The North Carolina State College research reactor [5].

The simplicity of the Water Boiler reactor has made it of interest as a laboratory tool for experimental work with neutrons and gamma rays and also to provide training in reactor operation, and ten such reactors were in operation or planned in the United States by the end of 1957. The first college-owned nuclear research reactor, which started operating at 10 kw in September 1953 at North Carolina State College, Raleigh, North Carolina, was of this type. It was completed after four years of planning, design, and construction, at a cost of $130,000 for the reactor, plus $500,000 for the reactor building and associated laboratory equipment. It differs from the Los Alamos SUPO in that the fuel container is a cylinder 11 in. in diameter and 11 in. high, rather than a sphere. Its experimental facilities include 12 access ports and a thermal column.

In June 1955, the reactor was shut down because of leaks which developed• in the fuel container and permitted the radioactive fuel to contaminate the inside of the reactor shield. After a major repair job, operation of the reactor with a new core was resumed in March 1957 at a power level of 500 watts, and the reactor has operated successfully at that level for a year.

7-2.4 Atomics International solution-type research reactors.

Several versions of the Water Boiler are being offered commercially by various companies. The major supplier is the Atomics International Division of North American Aviation Company which has built, or is building, 11 such reactors. Low-power reactors are: the l-watt Water Boiler Neutron Source (WENS) originally at Downey, California, which was moved to Santa Susana and modified to operate at 2 kw; a new 5-watt laboratory reactor (L-47) for Atomics International; the 100-watt Livermore Research Reactor at Livermore, California; and a 5-watt reactor planned for the Danish Atomic Energy Commission at Rise, Denmark. Higher power Water Boilers, operating at 50 kw, include the Kinetic Experiment for Water Boilers (KEWB-l) at Santa Susana; the UCLA Medical Facility at Los Angeles, California; and reactors for the Armour Research Foundation in Chicago, Illinois; the Japan Atomic Energy Research Institute at Tokai, Japan; Farbwerke Hoechst A. G. at the University of Frankfurt, West Germany; the Senate of West Berlin (Institute for Nuclear Research), Germany; and the Politecnico Enrico Fermi Nuclear Study Center at Milan, Italy.

FIG. 7-2. Armour Research Foundation research reactor (courtesy of Atomics International, a division of North American Aviation Co.)

The first solution-type research reactor for industrial use went into operation in June 1956. The general features of this reactor, which Atomics International built for the Armour Research Foundation at the Illinois Institute of Technology, Chicago, Illinois, are shown in Fig. 7-2.

The exposure facilities include one 6-in.-diameter beam tube extending radially to within 2 ft of the core tank and 4 in. in diameter from there to the core tank; two 4-in. and two 3-in. beam tubes extending radially to the core tank; two 2-in. through-tubes passing tangentially to the core tank; one l!-in.-diameter tube passing through the central region of the core; four 4-in. vertical tubes located in the reflector; one 5 ft x 5 ft graphite thermal column with a 12-in.-square removable section. The tube facilities consist of steel sleeves extending through the concrete shield and aluminum thimbles or liners which reach to the immediate vicinity of the core. Each tube facility is equipped with a graphite reflector plug and a dense concrete-and-steel shielding plug to be installed when the facility is not in use.

The horizontal thermal column is formed by a 5-ft-square column of graphite, in the center of which are nine removable graphite stringers. A large volume which may be used for exposures is provided between the end of the thermal column and the inner face of a movable concrete door. The thermal column access ports open into this volume.

To take advantage of the 50,000 curies of gamma activity produced by the fission-product gases circulating through the gas recombiner tank, exposure facilities are provided which extend from the subpiIe room into the exposure room and into the valve room. The facilities listed below consist of steel sleeves and aluminum thimbles which extend through the dense concrete walls of the exposure room.

2 gamma ports, 4 in. Diameter

2 gamma ports, 8 in. Diameter

1 rectangular gamma slot, 6 in. X 18 in.

In addition, two 4-in.-diameter gamma ports extend from the subpile room into the valve room. As with the beam tubes, each port is equipped with a plug to be installed for shielding purposes when the port is not in use.

7-3. The Homogeneous Reactor Experiment (HRE-1) [10-13]55

7-3.1 Introduction.

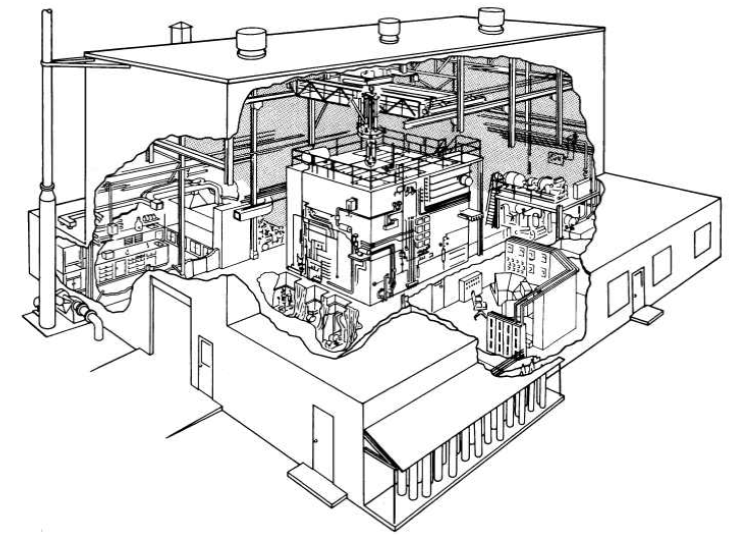

In 1950 the Oak Ridge National Laboratory undertook the task of designing, building, and operating a pilot-plant fluid-fuel reactor, the Homogeneous Reactor Experiment (HRE-l), shown in Fig. 7-3. The purpose of this reactor was to investigate the nuclear and chemical characteristics of a circulating uranium solution reactor at temperatures and powers sufficiently high for the production of electricity from the thermal energy released. Specifically, it was designed to operate with a full-power heat release of 0.6 to 3.5 million Btu/hr (200 to 1000 kw of heat), and a maximum fuel-solution temperature of 482°F, yielding, after heat exchange, a saturated-steam pressure of about 200 psi.

FIG. 7-3. The homogeneous reactor experiment (HRE-l).

During the 24-month period in which the reactor was in operation, starting in April 1952, liquid was circulated for a total of about 4500 hr. The reactor was critical a total of 1950 hr and operated above 100 kw for 720 hr. The maximum power level attained was 1600 kw. The reactor was shut down in the spring of 1954 and dismantled to make room for the Homogeneous Reactor Test (HRE-2), having successfully demonstrated the nuclear stability of a circulating-fuel reactor. The characteristics of the HRE-1 are summarized in Table 7-2.

7-3.2 The reactor fuel system.

The reactor core consisted of a stainless steel sphere 18 in. in diameter, through which was circulated 100 to 120 gpm of 93% enriched uranyl sulfate dissolved in distilled water. The temperature rise of the solution passing through the core was about 72°F at a power level of 1000 kw. The liquid was discharged from the core at a temperature of 482°F, and cooled to 410°F by evaporating water from the shell side of a Us-tube heat exchanger, thus generating about 3000 lb/hr of 200 psi steam. A canned-rotor centrifugal pump returned the fuel to the core to be re-heated. The total volume of solution in the high-pressure system was about 90 liters, of which 50 liters were in the core. A schematic flow diagram of HRE-l is shown in Fig. 7-4.

Table 7-2 Characteristics Of HRE-1

| Power, heat | 1000 kw |

| Fuel | UO2SO4 (93% enriched) in H2O |

| Fuel concentration | ~30 g U235 per liter (0.17 m UO2SO4) |

| U 235 in core | 1.5 - 2 kg |

| Core | 18 in. diameter, stainless steel |

| Pressure vessel | 39 in. ID, 3 in. thick, forged steel |

| Reflector | 10 in. D2O, pressurized with He |

| Specific power | 20 kw/liter |

| Fuel inlet temperature | 210°C |

| Fuel outlet temperature | 250°C |

| System pressure | 1000 psi (430 psi above vapor pressure) |

| Gas removal system | Vortex flow through core |

| Radiolytic gas recombination | CuSO4 (internal); flame and catalytic recombination (external) |

| Control system | Reflector level, safety plates, temperature control |

| Shielding | 7 ft barytes concrete |

| Steam temperature | 382°F |

| Steam pressure | 200 psi |

| Electrical capacity | 140 kw |

A total pressure of 1000 psi was maintained in the fuel system by heating a small volume of fuel to 545°F in a pressurizer chamber directly above the sphere. The 1000 psi total pressure, which is over 400 psi greater than is required to prevent boiling of the fuel solution, was necessary to minimize the volume of decomposition gases.

7-3.3 The reflector system.

The reflector of HRE-l was a 10-in. layer of heavy water surrounding the core vessel. The heavy water was pressurized with helium to within ±100 psi of the fuel pressure in order to minimize stresses in the 3/16-in. wall of the spherical fuel container. Both the reflector and the concentric core were contained in an outer pressure vessel of forged steel, 39 in. in inside diameter, with a 3-in.-thick wall. A 24-in., 1500-psi standard ring-joint flange at the top of the vessel permitted removal of the inner core.

FIG. 7-4. Schematic flow diagram, HRE-l.

In order to limit thermal stresses and to reduce corrosion of the steel vessel, the reflector temperature was regulated near 350°F. About 50 kw of heat conducted from the fuel core to the reflector liquid was removed. by circulating the heavy water with a 30-gpm canned-rotor pump through a reflector cooler which acted as a boiler feedwater preheater. A jet was located in this high-pressure circulating loop, the suction of which drew a continuous stream of gas from the vapor space above the reflector to a catalytic recombiner so that the concentration of deuterium and oxygen gases in this vapor space could be kept below explosive limits.

Some measure of nuclear control was obtained by changing the level of the reflector. The level could be lowered by draining liquid through a valve to storage tanks, or raised by starting a feed pump. This pump, which employed a hydraulically driven diaphragm with check valves, had a capacity of approximately 2 gpm against 1000 psi. Its intake was connected to supply tanks at atmospheric pressure, located below the reactor. These tanks also served as degas chambers for the reflector liquid which was discharged from the pressure vessel. Helium, water vapor, and D2 and O2 gas liberated here passed upward through a condenser to a small low-pressure catalytic bed where the O2 and D2 gases were recombined to D2O. Cold traps operated at -20°F were included in the reflector-system vent lines to prevent the loss of D2O or its contamination with H2O vapor.

7-3.4 The fuel off-gas system.

When the reactor was operating, without copper sulfate in the fuel solution, the fuel solvent (H2O) was decomposed by the energy of fission to yield a stoichiometric mixture of hydrogen and oxygen gas at a rate of 0.28 cfm (10 cfm at STP). In addition to this large volume of decomposition gases, there was also produced a very small volume (20 cc/day) of intensely radioactive fission gas, If these gases had not been removed and replaced by more liquid, excessive pressures would soon result, and since virtually all of this gas was liberated within the core, the displacement of fuel solution by the gas would make it impossible for the chain reaction to continue. For this reason, the gas was continuously separated from the fuel in the core by injecting the main circulating stream tangentially near the equator of the sphere, which caused the fluid to rotate and form a vertical cylindrical vortex approximately 1/4 in. in diameter. The centrifugal action of the rotating fluid served to separate the decomposition and fission gases from the liquid to the vortex, the axis of which was aligned with the fuel outlet. A nozzle with a central opening in the fluid outlet allowed the removal of gas from the vortex. This gas plus about 0.8 gpm of the fuel solution was passed through the outer annulus of a counter current, concentric-tube heat exchanger, which was partially cooled by 0.8 gpm flow of fresh makeup liquid being pumped back to the core. The cooled mixture of gas and liquid was then throttled through a valve into a gas separator which was connected to the fuel-solution storage tanks. The gas-steam mixture rose from the gas separator to a condenser immediately preceding a flame recombiner, so that the gases leaving the condenser were combustible and reunited to water in the flame of the recombiner shown in Fig. 7-4.

The flame recombiner is best described as an oversized Bunsen or Meeker burner enclosed in a water-jacketed cylinder. In the HRE-l no attempt was made to use this 40 kw of high-temperature heat, although in larger scale reactors this energy might be used to superheat steam about 70°F.

The exit gases from the flame recombiner contained only fission products and small amounts of unrecombined hydrogen and oxygen. They were passed through a catalytic recombiner which contained a platinized alumina catalyst to eliminate the traces of hydrogen and oxygen. Also, the catalytic bed was used to react the entire gaseous output at low reactor powers when insufficient gas was being liberated to maintain a steady flame at the burner of the flame recombiner. The catalytic bed was followed by a condenser and cold traps to prevent the loss of water from the system. The gas stream at this point was composed mainly of excess oxygen plus the highly active fission gases, mainly xenon, krypton, and their decay products. The activity of these gases was many orders of magnitude greater than the activity which can be discharged directly to the atmosphere without the construction of a very expensive stack; therefore it was desirable to provide some inexpensive means of storage for the dissipation of the radioactivity. This was accomplished by passing the gases through cold traps to remove moisture and adsorbing them onto water-cooled activated-carbon beds which were buried underground outside the reactor building. It is estimated that the equilibrium activity of the gases held on the carbon bed was 400,000 curies.56

The adsorption efficiency of the charcoal, even at ground temperature, was good enough to prevent a discharge of activity greater than a few curies per day. However, even this amount of activity had to be diluted so that the atmospheric concentration at ground level was not greater than 10-13 curies/co of air. Dilution was accomplished by feeding the active gas into a lO00-cfm ventilating air stream from the reactor shield and then to a 100-ft-high stack. During operation the gaseous activity inside the stack barely exceeded inhalation tolerance.

7-3.5 Fuel concentration control.

The condensate which was removed from the vapor-gas mixture upstream of the recombiner was returned either to the fuel storage tanks or to weighed holding tanks. The accumulation of water in the holding tanks provided a means of increasing the concentration of fuel in the storage tanks underneath the reactor. Since fuel was pumped continuously from the storage tanks to the high-pressure system by means of a duplex-diaphragm type pump at a rate of 0.8 gpm, it was possible to vary the concentration of the fuel which circulated through the reactor. Figure 7-5 shows how the core temperature varied with fuel concentration, in g/kg H2O. Furthermore, since the operating temperature of the core was controlled by the fuel concentration as shown in this figure, the operator had a convenient means of adjusting the solution temperature to the desired level. This feature of variable concentration was employed during startup of the reactor when the concentration had to be changed by large amounts, and also during steady operation for small changes in temperature. When sudden dilution of the fuel was desired, as in the case of a complete shutdown, the condensate holdup tanks were quickly emptied through a drain valve into the fuel-storage tanks, or condensate was pumped directly into the core.

FIG. 7-5. Dependence of critical fuel concentration on temperature in HRE-l.

The steep slope of the curve in Fig. 7-5-i.e., the large negative temperature coefficient-was a feature which was extremely important from safety and power-demand standpoints. For instance, a temperature rise of only 15°C was necessary to overcome a reactivity increase of 1 %, an amount considered very dangerous in most solid-fuel reactors.

7-3.6 Power removal.

The steam generated in the fuel heat exchanger was fed to a conventional multistage condensing turbine generator rated at 312 kva. With the reactor operating at 1000 kw and 250°C, a sufficient quantity of steam at 200 psi was produced to generate about 140 kw of electricity. Steam leaving the heat exchanger was first passed through a time-delay drum with a radioactivity monitor at the inlet and a quick closing valve at the outlet to prevent the escape of activity into the turbine system in the event of boiler tube failure. Small feed pumps returned the condensate from the turbine to the boiler.

Upon increase in generator load, the turbine governor opened the turbine throttle valves, increasing the steam demand, lowering the steam pressure and temperature, and reflecting itself into increased cooling of the uranium solution, which automatically increased the reactivity of the core and completely compensated for this increased load.

7-3.7 Internal-recombination experiments.

The use of copper dissolved in the reactor fuel for the complete recombination of radiolytic gas was successfully demonstrated in the HRE-l [14]. Copper ion was added as copper sulfate on four occasions, increasing the copper concentration to 10, 25, 75, and 150% of that necessary for complete recombination (i.e., 6.6 g CuS04/liter) in a static system at 250°C, at 1000 psig total pressure, and at a uniform power density of 20 kw/liter. The investigation was conducted at temperatures from 185 to 260°C, at pressures from 765 to 1200 psig, and at power levels as high as 1600 kw. In the main, the copper behaved as expected from static bomb tests. The highest power level for which all the gas was internally recombined was 1350 kw. In the course of all copper experiments, including 350 hr of operation at the highest copper concentration, 0.062 molar, no deleterious effects due to the presence of copper were observed.

7-3.8 Nuclear safety.

Although operating experience later verified early predictions of the inherent safety of this reactor, at the time of design it was considered judicious to incorporate conventional safety devices in the reactor for protection against potentially dangerous situations which might arise during low-power operation and until the dynamic stability had been demonstrated by experiment. Safety measures in the order of their automatic action as installed to limit reactor power or power doubling time were:

(1) Two magnetically coupled safety plates, worth about 45 g of uranium, which by falling in 0.01 sec caused the reactor temperature to be lowered from 250°C to approximately 243°C.

(2) Dumping of the reflector.

(3) Dilution of the fuel (this was the normal shutdown procedure).

(4) Stopping of the steam extraction by closing either a steam valve or the turbine governor.

(5) Draining the fuel solution to the noncritical-geometry tanks below the reactor.

Experiments demonstrated that the reactor was extremely fast-acting with respect to limiting power surges and led to the belief that mechanical control devices were unnecessary [15]. These consisted of a series of kinetic experiments in which the power responses to reactivity increases were observed. First, the entire range of normally available reactivity increases -fuel concentration, rod withdrawal, and reflector level-was tested with initial power levels as low as 10 watts and reactivity rates up to 0.05% per second. Then, in order to provide more drastic tests, the main fuel circulating pump was stopped, the reactor was maintained at a low power and at high temperature, but the heat exchanger was cooled about 100°C. When the pump was restarted, the cold fuel from the heat exchanger was rapidly injected into the core, producing a rate of reactivity increase of as much as 0.8% keff per second. The results of two experiments in which only the initial powers differed are shown in Fig. 7-6 the power increased in a period as short as 35 msec, reaching a peak of 10 Mw in 1 sec, and then approached the equilibrium power demand within 0.2 sec after the peak. The calculated pressure rise associated with the peak power of 10 M w was only 5 psi.

In these experiments the worst combination of circumstances was imposed on the reactor. It was successfully demonstrated that the HRE-l was sufficiently stable to withstand nuclear transients greater than those expected from operating errors.

7-3.9 Leak prevention.

A major problem in the HRE-l was to maintain absolute leaktightness in all components. The radioactivity of the solution during operation was about 30 curies/co. Twenty-four hours after shutdown the activity was about 3 curies/co, With these high activities, the total leakage from the system had to be kept below 1 cc per day. A much better performance than this was attained through the use of canned-rotor pumps, double tube-sheet exchangers, and bellows-sealed valves.

All welded joints were made with extraordinary care and tested by several non-destructive methods before being approved for use. Flanged joints were assembled with stainless steel ring gaskets of oval cross section and each joint contained a leak detection device for constant monitoring (see Fig. 7-13). In addition, the ventilating air which flowed through each equipment compartment was monitored constantly with gamma-radiation detection devices. Although several leaks were experienced in the startup phases, no leakage was found during the final 12-month period.

Table 7-3

Hre-L Construction Cost Summary*

|

Total | % of total |

| Building | $ 300,000 | 27.5 |

| Fuel and reflector equipment and piping | 420,000 | 38.2 |

| Instrumentation | 190,000 | 17.6 |

| Shield | 110,000 | 9.7 |

| Power system | 80,000 | 6.9 |

| Total construction cost for HRE-l | $ 1,100,000 | 100.0 |

* These costs include material, labor, and allocated overhead. |

FIG. 7-6. Power response of HRE-l during reactivity increase of 0.8% k./sec.

7-3.10 Shielding.

As with all nuclear reactors, personnel had to be protected from the high radiation levels which existed in the vicinity of the reactor core. In the HRE-l this protection was provided by a 7-ftthick shielding wall of high-density concrete. An increase in the density of the concrete from 2.3 to 3.5 glee resulted from the use of barium sulfate ore as the aggregate material. The shield was a departure from most reactor shields in that it was constructed of loosely stacked block with only the outer 16-in. layer of blocks being mortared.

7-3.11 Construction cost.

The total construction cost of the reactor was $1,100,000, which did not include the cost of fuel and heavy water. Table 7-3 is a summary showing the cost of various parts of the system.

7-3.12 Maintenance.

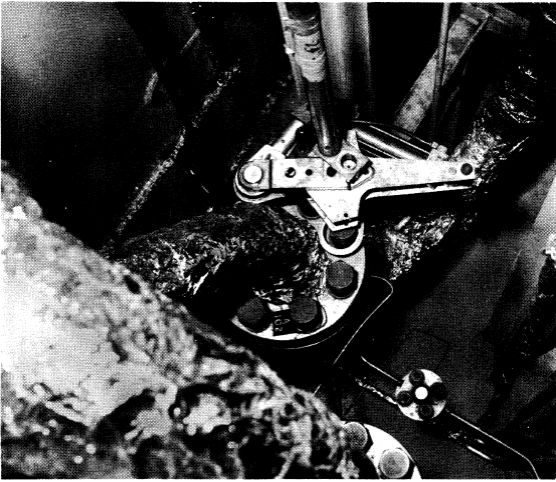

The maintenance of homogeneous reactors is greatly complicated by the radioactivity of the parts, and in the HRE-l it was often necessary to decontaminate equipment and to provide temporary protective shielding before repair work could be done. In most cases the repair work had to be done with long-handled tools, which made the job even more difficult. By the use of decontamination, shielding, and extension tools, it was possible, however, to make a number of major repairs in radiation fields as high as 2000 r /hr, without exposing personnel beyond accepted tolerances. In this regard remote viewing devices such as mirrors, binoculars, and a Polaroid Land camera were found to be invaluable tools. The main circulating pump was replaced or repaired three times under such conditions and the diaphragm feed pumps twice. In fact, in no case of a breakdown was it impossible to make the necessary repairs.

7-3.13 Dismantling the HRE-l.

After final shutdown-of the HRE-l the reactor was decontaminated in preparation for disassembly. Over a period of 30 days, starting with activity levels of the order of 1000 r/hr, the activity was reduced sufficiently to permit dismantling of the system with long-handled tools [16].

The decontamination treatment consisted of repeated washing alternately with 35% HNO3 and aqueous solutions of 10% sodium hydroxide, 1.5% sodium tartrate, and 1.5% hydrogen peroxide. The over-all decontamination factors were 22 to 25, including decay, but the factor for decontamination with a single reagent was only between 1 and 2.25. Large amounts (of the order of 103 curies) of cerium, zirconium, barium, lanthanum, strontium, niobium, and ruthenium were removed. The significant contaminants remaining were zirconium and niobium, which were bound in the oxide film. Although these could have been removed from the system by descaling the oxide corrosion film, which would have given a further decontamination factor of approximately 100, such a treatment would have made it impossible to determine that no significant corrosion had taken place during nuclear operation.

7-3.14 Critique of HRE-l [17].

After the HRE-l was put into operation, personnel associated with the Homogeneous Reactor Project were asked to suggest ways in which the design and construction of the reactor and the associated development program might have been improved. More than one hundred specific design changes were recommended, many of which related to the difficulty of operating the reactor on a continuous basis and the need for repairing and/or replacing faulty equipment. Among the many possible improvements recommended' were the use of high-pressure catalytic recombination; external gas separation (i.e., nonvortex core flow); spacing of equipment for easier inspection and maintenance; shielded, waterproof instrument lines; instrumentation for more accurate fuel accountability; improved feed pumps; and provision for obtaining meaningful corrosion data.

The general conclusion reached was that the reactor construction schedule (16 months) was too accelerated to allow good design and construction practices to be put fully into effect. The component development and testing program, in particular, suffered by the short time schedule in that pieces of equipment such as valves and pumps were not completely tested before being used in the reactor.

The thorough analysis of the HRE-l design provided a basis for the subsequent design of the HRE-2, in which many of the suggested improvements were incorporated. These included: (a) greater accessibility of equipment, (b) provision for flooding cells, (c) better shield construction with metal walls to permit decontamination, (d) more accurate means for measuring fuel inventories, and (e) elimination of screw-type fittings.

7-3.15 Summary of results.

As a result of the operation of the ~RE-l and of the extensive experimental program conducted with it, several un-certainties were resolved regarding the nuclear and chemical behavior of aqueous homogeneous reactors at the high temperatures and high' pressures required for power generation. Included were demonstrations of (1) a remarkable degree of inherent nuclear stability, a result of the very large negative temperature coefficient of reactivity, (2) the elimination of the need for mechanical control rods as a consequence of this inherent stability, (3) flexibility and simplicity of fuel handling, (4) stability of the fuel, (5) the ability to attain and maintain leaktightness in a small high-pressure reactor system, (6) the safe handling of the hydrogen and oxygen produced by radiation decomposition of the water, and (7) the direct dependence of reactor power upon turbine demand.

7-4. The Homogeneous Reactor Test (Hre-2)57

7-4.1 Objectives.

The objectives of the Homogeneous Reactor Test (HRE-2) are (1) to demonstrate that a homogeneous reactor of moderate size can be operated with the continuity required of a power plant, (2) to establish the reliability of engineering materials and components of a size which can be adapted to full-scale power plants, (3) to evaluate equipment modifications which will lead to simplifications and economy, (4) to test simplified maintenance procedures and in particular underwater maintenance, and (5) to develop and test methods for the continuous removal of fission and corrosion contaminants.

7-4.2 Reactor specifications and description [15,18].

The bases for the design of the reactor, which are summarized in Table 7-4, were selected early in 1954 and were intended to take fullest advantage of the progress in chemistry, materials and component development, and the experience with the HRE-l. In order that the objective of a significant test of the engineering feasibility of a large power station be satisfied, it was necessary that the physical size of the reactor and its auxiliaries be increased appreciably beyond that of HRE-l. To hold the cost within reasonable bounds for an experiment, it was decided to limit the power output and thus the expense for heat-removal equipment, and also to install the reactor in the building which had previously housed HRE-I, permitting the use of many of the existing site facilities. The size of the reactor core represents a compromise between two objectives, attainment of high specific power required for economy in a large plant and evaluation of the fabrication and durability of a zirconium-alloy core tank. The power output was, therefore, set at 5000 kw (heat) with the possibility of a maximum 10,000 kw, and the core diameter at 32 in. Although these together result in a low specific power of 17 kw/liter in the core at 5000 kw, this was considered acceptable, since operability at a relatively high specific power of 30 kw /liter had been demonstrated in the HRE-l. Another factor affecting the selection of core diameter was the opinion of fabricators that current technology would be exceeded for a zirconium vessel larger than 32 in.

Table 7-4

Design Bases For Hre-2

| Power, heat | 5000 kw |

| Temperature, core outlet | 300°C |

| Pressure | 750 psi in excess of vapor pressure (see text) |

|

2000 psi maximum total pressure |

| Core diameter | 32 in. |

| Core solution | UO2SO4, in D2O (~ 10 g U235 per liter) |

| Blanket | D2O |

| Fuel circulation rate | 400 gpm |

| Blanket circulation rate | 230 gpm |

| Core flow pattern | Straight-through |

| Core construction material | Zircaloy-2 |

| System construction material | Type-347 stainless steel |

| Radiolytic-gas removal | External pipeline separator |

| Radiolytic-gas recombination | Low-pressure system: platinized alumina catalyst |

|

High-pressure system: CuSO4, in solution |

| Fission-product-gas disposal | Decay on activated carbon |

| Control |

|

| Normal | Variable solution concentration |

| Safety | Temperature coefficient |

The increase in fuel temperature from 250°C in the HRE-1 to 300°C was based upon the more favorable corrosion resistance of both stainless steel and Zircaloy-2 to dilute uranyl sulfate at the higher temperature and the possibility of improved thermal efficiencies. Also the temperature at which the two-liquid phase region appears is higher for the more dilute fuel, permitting this increase.

Table 7-5

Hre-2 Design Parameters

|

Core | Blanket |

| Power, heat, kw | 5000 | 220 |

| Pressure, psi | 2000 | 2000 |

| Vessel |

|

|

| Inside diameter, in. | 32 | 60 |

| Thickness, in. | 5/16 | 4.4 |

| Material | Zircaloy-2 | Stainless-steel-clad |

|

|

carbon steel |

| Volume, liters | 290 | 1550 |

| Specific power, kw /liter | 17 | 0.14 |

| Solution | UO2SO4-D2O | D20 |

| Uranium concentration, g of |

|

|

| U235 per kg D2O | 9.6 | 0 |

| Circulation rate, gpm | 400 | 230 |

| Inlet temperature | 256°C | 278°C |

| Outlet temperature | 300°C | 282°C |

| Volume of gas generated, |

|

|

| ft3/sec at STP | 0.96 | 0.013 |

| ft3 /sec at 2000 psi, 280°C | 0.015 | - |

The design pressure of 2000 psi resulted from the necessity for an over-pressure on the system to prevent boiling, to reduce the volume of gas in the core, and to increase the efficiency of the copper catalyst. A maximum pressure of 750 psi was thus provided in excess of the vapor pressure of water of about 1250 psi at 300°C.

The thickness of the blanket of 14 in. between the core and pressure vessel was selected as a compromise between neutron leakage and the use of a simple pressure vessel of dimensions within the means of standard fabrication techniques.

The fuel circulation rate of 400 gpm was based upon heat-removal requirements and the availability of suitable pumps. Pumps capable of this output had been successfully operated under comparable conditions.

The vortex-type flow through the core of HRE-l was abandoned in favor of straight-through flow because hydrodynamic experiments demonstrated the pressure drop of the former to be excessive for larger cores. As a result, the extraction of radiolytic gas directly from the core was excluded, and an external gas separator in the exit pipe from the core was used to separate gases produced in the core. The amount of these gases depends on the operating temperature and pressure and the CuSO4 concentration. The excess gases are recombined at low pressure but by means of a platinized alumina catalyst instead of combustion in a flame-type recombiner as in the HRE-l.

In stagnant fuel lines external to the core, the radiolytically generated oxygen is insufficient to replace the oxygen consumed in reacting with the stainless steel to form metallic oxides. Since an oxygen deficiency induces hydrolytic precipitation of the uranium, approximately 2 liters/min (STP) of gaseous oxygen are injected into the fuel feed stream, maintaining a concentration of approximately 500 ppm in the high-pressure system. The disposal of the fission-product gases which are stripped from the fuel by the excess oxygen and radiolytic gas is accomplished by adsorption and subsequent decay on beds of activated carbon. Experience with this method of disposal was completely satisfactory in the HRE-l.

To reduce the xenon content of the core solution and minimize the catalyst-poisoning effect of fission-product iodine on the recombiners, an iodine-absorption bed of silver-coated wire mesh was installed in the off-gas line between the fuel dump tank and the recombiners. The bed removes over 99% of the iodine passing through it, and will retain the absorbed iodine at temperatures up to 450°C.

Type-347 stainless steel was designated as the material of construction for all of the reactor except the Zircaloy-2 core vessel. Titanium was chosen to reinforce certain points of high turbulence, such as the pump impellers and the gas separator. Previous corrosion and welding experience with this grade of stainless steel, also used for HRE-l, has been excellent.

Based on HRE-l experience, it was decided to eliminate mechanical control devices and depend entirely on varying the fuel concentration for shim control, on temperature coefficient for transient nuclear changes, and on dumping the fuel solution for rapid shutdown when required.

The design parameters of HRE-2 are summarized in Table 7-5.

The Bow diagram for the reactor is illustrated in Fig. 7-7. Since the fuel and blanket systems are virtually identical-the only significant differences being the absence of a blanket iodine separator and the larger vessels necessary to accommodate the greater volume of blanket fluid-the entire blanket system is not shown. The fuel system is described as follows.

FIG. 7-7. Flowsheet of HRE-2.

In the high-pressure system the fuel solution is pumped into the bottom of the reactor core at 256°C and is heated to 300°C as it proceeds upward to the outlet pipe. At the top of the outlet pipe is attached the pressurizer in which condensate is electrically heated to a maximum temperature of 335°C to produce 2000-psi steam. The fuel flows past the pressurizer to the gas separator, where directional vanes cause the fluid to rotate sufficiently to separate the radiolytic gas (D2 and O2), the excess O2, and fission product gas. The separated gas forms a vortex along the axis of the pipe and is bled to the low-pressure system. The reactor solution continues from the gas separator to the U-tube primary heat exchanger, where it is cooled from 300°C to 256°C by transferring heat to the boiler feed water surrounding the tube bundle. The 244°C, 520-psi steam produced on the shell side of the heat exchanger is bled partially to the small (345-kva output) turbine generator remaining from the HRE-l and partially to an air-cooled steam condenser. The uranyl sulfate solution flows next to the intake of the 400-gpm canned-motor circulating pump and thence is pumped to the core for reheating. The blanket fluid follows an identical cycle at a flow rate of 230 gpm. This lower flow rate was based on a pump of the same horsepower but designed to circulate a thorium oxide suspension, rather than pure D2O.

The gases and some entrained liquid removed by the gas separator are transferred to the low-pressure system through a "letdown heat exchanger," a jacketed pipe which cools the gas-liquid mixture to 90°C. A valve downstream of the heat exchanger throttles the gas-liquid stream to atmospheric pressure. The mixture then discharges into the "dump" tanks, which have sufficient capacity to hold all the reactor liquid. An evaporator bunt into the dump tanks provides continuous mixing and, more important, steam for dilution of the deuterium and oxygen below the explosive limits. The gas-and-steam mixture flows upward through the iodine bed to the catalytic recombiner, in which the deuterium and oxygen react on a bed of platinized alumina pellets to form water vapor. The heavy water is condensed by the shell-and-tube condenser following the recombiner and normally flows back to the dump tanks. However, the water may be diverted to weighed storage tanks in case it is desired to change the concentration of the fuel solution. Water which is returned to the dump tanks is mixed with the excess fuel solution stored there (approximately 25 gal) and then fed to the intake of a sealed-diaphragm injection pump, which returns the liquid to the high-pressure circulating system at a rate of about 1 gpm, thus constantly replacing the liquid removed via the gas separator.

FIG. 7-8. HRE-2 shield and vapor container.

The small volume of intensely radioactive fission gas plus the excess oxygen remaining after condensation of the re-formed heavy water is dried in cold traps at -23°C and sent to the beds of activated carbon for a period of decay. Gas leaving the bed is diluted with 1400 cfm of air and discharged to the atmosphere from a 100-ft stack.

Samplers are provided to secure small quantities (5 ml) of the fuel and blanket liquids from the high- and low-pressure systems for chemical analysis. These units are located in bypass lines; material circulated through them is trapped by closing the sampler inlet and exit, after which the contents are discharged into. a portable container through a drain valve.

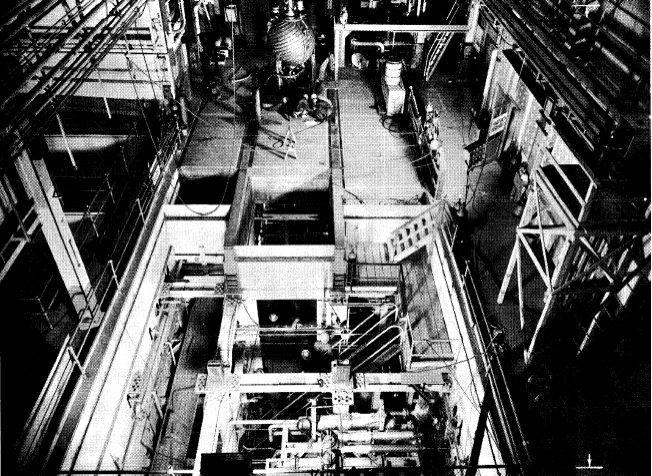

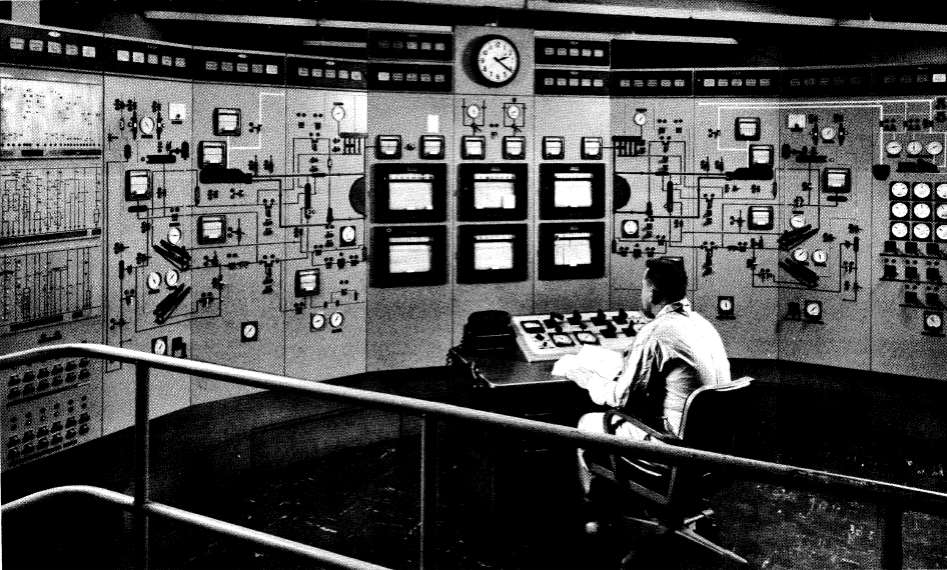

All the primary reactor equipment is located in an underground, boxlike, steel tank called the "shield pit," shown in Fig. 7-8. The design of the shield pit was influenced by several factors, including a requirement for accessibility and flexibility because of the experimental nature of the installation, provision for complete containment of the contents of the reactor should a leak develop or should the pressure vessel or heat exchangers rupture, efficient utilization of the space within an existing structure, and capability of flooding with water for maintenance or replacement operations.

The reactor shield pit occupies the center high-bay area of the building and is constructed of 3/4-in. welded steel plate reinforced in such a manner that an internal pressure of 30 psi will be contained. This pressure corresponds to the instantaneous adiabatic release of the entire contents of the reactor system. The chemical processing cells, each 12 ft wide by 25 ft long, are designed similarly.

The upper surface of the blocks forming the roof of the shield pit is at ground level. This roof is made of high-density concrete 5 ft in total thickness and consists of two layers of removable slabs with a completely welded steel sheet sandwiched between the layers and extending across the top of the pit to form a gastight lid. The roof blocks are anchored to the girders and supporting columns by means of a slot-and-key arrangement, shown in Fig. 7-8. The vertical columns are embedded in a concrete pad which is 3 ft thick and is heavily reinforced with steel.

The wall between the reactor pit and the control area is a hollow box 5t ft wide, constructed of 1/2-in. steel plate welded to the north side of the reactor shield tank. It is filled with high-density barytes, sand, and water. The use of the fluid shield between the reactor and control-room areas allows flexibility in the locations of service piping and instrument or electrical conduits. All lines leaving the reactor tank are welded into the shield wall; conduits are connected into junction boxes inside the pit with gastight seals on the individual wires.

The design is such that nowhere outside the shield will the radiation dosage exceed 10 mrep/hr when the reactor is at 10 Mw. For the purpose of decreasing the neutron activation of equipment inside the pit, the reactor vessel is surrounded by a thermal neutron shield consisting of a steel tank with a 2-ft-wide annulus filled with boron ore and water.

FIG. 7-9. HRE-2 component arrangement, plan view.

FIG. 7-10. HRE-2 container looking southeast (at 50% completion).

FIG. 7-11. Reactor tank with shielding plugs in position during hydrostatic test.

The arrangement of reactor components within the main reactor pit is shown in Fig. 7-9. The reactor is near the center of the pit, enclosed by the 2-ft-thick thermal shield. To the left of the reactor is all the fuel-system equipment, and to the right is the blanket equipment.

Most of the high-pressure components are located close to the pressure vessel. The pressurizers are positioned directly above the reactor; the gas separators are in the S-shaped outlet lines to the steam generators on the south side of the pit. The areas to the left and right of the reactor in the center bay are reserved for future equipment modifications or additions.

To the far left is grouped all of the fuel low-pressure equipment, including dump tanks, recombiner, condensate tank, and cold traps. These components are assembled on a rigid structural-steel frame; the blanket low-pressure equipment is to the far right.

Insofar as possible, valves are situated close to the control-room wall so that air lines and leak-detector lines can be kept short. The arrangement of the valves is such that all flanges can be easily disconnected from above.

7-4.3 Schedule of construction [1920].

Construction of the HRE-2 was started in July 1954, immediately after the dismantling of HRE-l. The initial step was the excavation of a large hole beneath the building (which had previously housed the HRE-l) for the large rectangular steel tank (60 ft long, 30½ft wide, and 25 ft deep) which contains the reactor and its associated equipment. Figure 7-10 shows this tank at approximately 50% completion.

The north wall of the reactor tank, seen to the left in Fig. 7-10, is common to both the reactor tank and the control-room area, and it is through this wall that the many service, instrument, and electrical lines which must interconnect these two areas pass. The next step in the construction was to install the approximately 600 lines which penetrate this 5½-ft-thick wall.

Figure 7-11 shows the tank after the complete roof structure had been assembled and welded closed as it was prepared for a hydrostatic test. In this test the tank was filled with water and then pressurized to give the equivalent of a 30-lb internal pressure at all points within the tank. Strain gauges were attached at many points so that the complicated stress pattern could be studied in some detail for assurance that the tank was safely within design limits.

While the reactor tank and control-room areas were being constructed, reactor equipment was being procured and constructed at several places. Much of the equipment required in the low-pressure system had been inspected and tested when the container was completed. In November 1955, these parts and the thermal shield surrounding the reactor pressure vessel were installed. Figure 7-12 shows the reactor core and pressure-vessel assembly just before installation in January 1956.

FIG. 7-12. View of HRE-2 building, main bay.

FIG. 7-13. Artist's concept of homogeneous reactor test, HRE-2.

FIG. 7-14. HRE-2 leak detection system.

The heat exchangers were subsequently installed and followed by the main circulating pumps so that the high-pressure piping which connected the pumps, heat exchangers, and pressure vessel could be attached. This work occupied most of the months of February and March. Construction of the reactor was completed in May 1956. Figure 7-13 is an artist's concept of the completed reactor.

7-4.4 Nonnuclear testing and operation.

Pretesting, operation of the reactor as a nonnuclear facility, and a lengthy flange-replacement job occupied the period from completion of construction in May 1956 to December 1957. A chronological summary of the events associated with the nonnuclear operation of the reactor during this period is shown in Table 7-6.

From Table 7-6 it can be noted that preoperational testing of HRE-2 was interrupted by stress-corrosion cracking difficulties, which were caused by chloride ion contamination in the stainless steel tubes that are used to detect and prevent leakage of radioactive solution from flanged joints [20]. Figure 7-14 shows how an individual leak-detector line is attached to the groove of the ring-joint flange. The tubes from all the flanges terminate at a valve header station in the control room. Normally this system is kept pressurized with water to a pressure of 300 to 500 psi above the system pressure. A leak in any flange results in leakage of water from the header and a loss in pressure, which actuates an alarm at a fixed level above the fuel or blanket pressure. This is normally a sensitive and satisfactory means of preventing the leakage of radioactive liquid from the reactor (the leak-detector fluid leaks out instead) and detecting the leaks when they do occur (by measuring the pressure or volume loss of the leak-detector fluid). Volume changes in the header can be read to ±1 cc from a graduated scale next to each header sight-glass. By observing level changes at regular intervals, noting which lines are isolated from the header, leaks of less than 2 cc per day can be detected.

Table 7-6

Summary Of Hre-2 Nonnuclear Operation

Period |

Test or event |

| May 1956 | 3000-psig hydrostatic test of high-pressure system and 750-psig test of low-pressure system |

| June 1956- July 1956 | Cleaning of piping systems with 3% trisodium phosphate followed by 5% nitric acid and initial operation of pumps. Tests for dump-tank entrainment and efficiency of catalytic recombiner |

| July 1956- August 1956 | Initial tests of equipment removal and underwater maintenance |

| August 1956- October 1956 | Flushing of flange leak-detector tubes to remove chloride contamination |

| October 1956- November 1956 | Initial nonnuclear operation of reactor at 2SOoC and 2000 psig. Thermal cycling of flanged joints |

| December 1956- January 1957 | Removal of typical flanges for metallographic examination to detect possible stress-corrosion cracks. Further tests of remote-maintenance tools. |

| January 1957- March 1957 | Further operation of the reactor with water and with depleted uranium at various conditions of temperature and pressure |

| April 1957- August 1957 | Removal, inspection, and replacement of flanges and leak-detection tubing |

| August 1957- September 1957 | Re-cleaning of system with trisodium phosphate and nitric acid solutions and hydrostatic testing |

| September 1957- October .1957 | Final operation at design conditions with water and with depleted uranium. Final leak test of reactor piping with radioactive tracers |

| November 1957- December 1957 | Final insulation of reactor piping; installation of new refrigeration system and new iodine absorption bed, followed by nonnuclear operations with heavy water. Criticality achieved December 27, 1957 |

Since this system is a secondary portion of the reactor, the leak-detector tubing unfortunately did not receive the same attention from the standpoint of specification and materials control as the stainless steel used in the primary piping. The 1/4-in. type-304 stainless steel had been purchased to standard ASTM tubing specifications, but in 30- to 4O-ft lengths instead of the usual 20-ft lengths. The tubing was received and installed without difficulty. It was given a hydrostatic test after installation and put in service with distilled water. After approximately three months it was observed that some of the water drained from the leak-detector system was badly discolored. An analysis revealed the liquid to contain approximately 1000 ppm of chloride. Since conditions of operation up to this point had been relatively mild, it was thought that the chloride might be removed simply by flushing, and approximately six weeks were devoted to disassembling the reactor and washing out all detectable indications of that contaminant.

After discussions with the tubing manufacturer it was concluded that the chloride had originated from a die-drawing compound which had not been removed from the inside of the tubes prior to annealing. The presence of the chloride-containing hydrocarbon caused carbide precipitation at the grain boundaries during annealing and created tiny caves into which the chloride penetrated. The pickling and cleaning treatment which followed did not remove this material; in fact, it was learned that the manufacturer's pickling tanks did not accommodate the full length of the tubing, making it necessary to pickle by dipping approximately half the tubing at a time. The net result was that large quantities of chloride remained inside the tubing to be leached out later when filled with water.

At the time the stress-cracking damage was discovered late in 1956 the reactor had been mane ready for a series of engineering tests, and for this reason it was decided to make a brief inspection of the damage resulting from the chloride contamination before proceeding with the planned experimentation. This preliminary inspection provided the basis for a decision to prepare for the replacement of the 259 flanges and the 15,000 ft of leak-detector tubing in the system. It was further decided that engineering tests which had been interrupted could proceed for the period of approximately three months which would be required to procure new flanges and leak-detector tubing.

Dismantling of the system was begun in April, and a very careful inspection of the 259 flanges was made to determine how many should be replaced. The Super-Zyglo dye-penetrant method of flaw detection was chosen as the most sensitive test which could be used practically in the field.

Of the 259 flanges inspected, 167 were found to be acceptable (i.e., as good as new), 67 were rejected because of cracks, pits, or other possible flaws, and 25 were judged questionable. Nearly all of the rejected flanges were in high-temperature portions of the reactor. While the inspection method was selected as the best available, it was not judged to be infallible; e.g., differentiation between mechanical scoring and corrosion pitting was not always clear-cut, and any cracks covered by smeared metal resulting from excessive gasket pressure could not be detected. Hence it was decided to replace all the high-temperature flanges with new flanges or, where this was not possible, to remove 0.02 in. of metal from the flange surfaces. A total of 132 flanges were replaced; 15 were re-machined. In addition, the 1/4-in. stainless steel tubing to all the high-pressure flanges (approximately 10,000 ft) was replaced in the leak-detector system. This repair work was completed in August 1957.

To remove any organic material introduced during repairs and to pretreat the fresh metal surfaces incorporated into the system, the reactor piping was subsequently flushed with hot 3% trisodium phosphate solution, followed by water rinses and a 5% nitric acid wash. After hydrostatic testing the reactor was test operated with condensate for 150 hr at 280°C, then charged with depleted uranyl sulfate solution. Test operation with depleted uranium included: (1) a series of concentration and dilution experiments to study the transient and equilibrium behavior of ions in the system, (2) checking of the inventory-control methods by comparing the fuel analyses and indicated system controls with the quantity originally charged, and (3) observation of the corrosion behavior by analysis of fuel samples during a 159-hr run at temperatures above 250°C. At the conclusion of the run the charge was recovered and found to agree well with the computed inventory, although chemical analyses of high-pressure-system samples during operation had indicated a uranium concentration 5 to 10% lower than the amount added would predict. Nickel analyses of the fuel solution pointed to a system corrosion rate of slightly less than 1/2 mpy.

Before the reactor was charged with enriched fuel, the piping and shield were subjected to careful leak tests. To obviate the presence of helium in the piping in case further testing with helium-became necessary, the reactor was first pressurized to 500 psig with nitrogen, to which was added 40 curies of Kr85 as a tracer gas. The shield was sealed-and the reactor allowed to stand pressurized for five days, after-which air samples were drawn from the shield and heat-exchanger shells for beta-activity, scanning to detect the presence of any leaking krypton. This test was inconclusive at the time, however, because of difficulties encountered in purifying the samples for counting. Large samples of the air being tested were stored in gas cylinders; then the piping was vented and re-pressurized with helium. After an additional waiting period the sealed volumes were again checked using helium leak detectors sensitive to 1 ppm of helium in air. This test demonstrated that the piping leakage was less than 0.2 cc/day of helium, with a pressure differential of 15 psi across the leak. These results were subsequently confirmed by krypton data after analytical difficulties were resolved.

With the integrity of the reactor piping established, the seal pans were welded in place on the shield roof, and the roof plugs were locked in place. By pressurizing the shield and flooding the roof with water, leaks in the seal pan welds were located for subsequent repair. The major shield leak was found to be through a 16-in. valve in the ventilating duct; when this was repaired, the total leakage fell from 25 cfm to approximately 1/2 cfm. The shield was judged sufficiently tight at this point to proceed with the critical experiments, after which repairs were continued. By painstaking individual checking of all shield penetrations and the use of thermosetting resin to seal the metal lips to which the roof seal pans are welded, the leakage was finally reduced to 4 to 4.5 liters/min at 15 psig.

7-4.5 Nuclear operation [21].

Fuel charging began on December 24, and criticality was achieved on December 27, 1957, with the core and blanket near room temperature and at a pressure of about 800 psig. Nuclear instrumentation for the test consisted of three fission chambers, viz., two permanent chambers in the instrument tube outside the reactor pressure vessel and a temporary chamber inside the blanket vessel. An antimony-beryllium neutron source was suspended in the thimble in the center of the core (see Fig. 7-18).

The reactor was brought gradually to the critical condition by the in-jection of enriched uranium into the fuel solution added to the dump tanks in batches of 100 to 400 g. Fuel feed pumps and purge pumps were operated continuously to provide mixing between the dump tanks and the high-pressure system. Following each addition the solution concentration in the high-pressure system was allowed to reach steady state, as indicated by a leveling-off of fission count rates. After 2060 g of U235 had been added and the 'temperature of the solution lowered to 29°C, the neutron source was withdrawn. At this point, the fission count rates continued to rise, indicating that criticality had been achieved. Raising the temperature of the reactor slightly by pumping warm water through the heat exchangers stopped the nuclear chain reaction. By further varying the temperature and concentration of the fuel solution, it was demonstrated that the nuclear reaction could be easily and safely controlled in this manner.

After the initial critical experiment the neutron source was moved from the core to the blanket thimble, and the reactor was brought to criticality seven times at successively higher temperatures ranging up to 281°C. In each experiment the reactor temperature was raised above the desired point by supplying steam to the heat exchangers, and a batch of fuel solution was injected into the dump tanks. After steady count rates showed complete mixing of the new fuel, the temperature was slowly lowered until the critical temperature was reached. It was held at this point for about 1/2 hr before proceeding to the next experiment. Figure 7-15 compares the experimental measurements of the HRE-2 critical concentration as a function of temperature with concentrations calculated by various methods. It can be seen that the two-group calculations predicted values about 20% below those observed. The harmonics calculation, which used a convolution of an age and a Yukawa kernel to represent slowing down in D2O, gave quite satisfactory results. The multigroup calculation also gave results in agreement with the experimental data.

The first operation of the reactor at significant power levels took place in February 1958. In April 1958 the power level was raised in steps of 1 Mw to the design power level of 5 Mw. Operation was exceptionally smooth, and no mechanical difficulties were encountered in the first 500 hr after charging the reactor with U235. Unfortunately, shortly after reaching full-power operation a crack developed in the tapered portion of the zirconium core tank, permitting fuel solution to leak into the blanket. After a series of tests to determine the magnitude of the leakage and calculations to determine the behavior of the reactor with fuel in the blanket, it was decided to operate the reactor as a one-region machine (i.e., identical fuel solution in core and blanket). Operation of the reactor under these conditions was resumed in May 1958.

7-4.6 Operational techniques and special procedures. Reactor startup.

As the size of homogeneous reactors increases, the use of control-rod neutron absorption to perform a startup becomes progressively less attractive; e.g., to maintain criticality in HRE-2 while heating from 20 to 280°C re-quires a reactivity increase of more than 25% ∆k because of the large negative temperature coefficient. It is much more convenient to provide a means of varying the amount of fuel in the core as required to overcome temperature and power coefficients.

During the initial experimental stage of HRE-2 operation, startup was begun by evaporating heavy water from the dump-tank solutions, condensing, and pumping to the core and blanket circulating loops. The filled loops were then pressurized, circulation was initiated by starting the canned-motor pumps, and the circulating stream was preheated to operating temperature with an auxiliary heat source. The concentrated fuel was then pumped from the dump tanks to achieve criticality.

FIG. 7-15. Critical concentration of HRE-2 8S 8 function of temperature.

An alternate procedure involves starting the reactor without preheating by varying the fuel concentration. When sufficient fuel has been added to raise the reactor temperature to its normal operating level, power withdrawal is begun. Temperature adjustments may be made by removing pure solvent to temporary storage tanks or adding pure solvent to the circulating fuel solution.

A variation of this procedure is to fill the reactor slowly with fuel of the final concentration. In this case the reactor will become chain-reacting at a low temperature with the core tank only partially filled with fuel solution. As the quantity of liquid in the core is slowly increased, the temperature will rise until the desired temperature is attained with the core completely full.

The time required for startup is determined by the rate at which heating can be permitted. The same limitations apply to homogeneous reactors as to other reactors in this respect. Generally, the heating rate of 100°F /hr is considered reasonable and unlikely to produce excessive stresses. Probably more important, but more difficult to determine, is the temperature difference which exists across heavy walls. Keeping these temperature differences to less than 100°F prevents excessive stresses. Once the temperature limitations are established, the startup rate of fuel addition can be set to match them.

Thus, although aqueous homogeneous systems have been demonstrated to be inherently stable, restrictions are nevertheless placed upon the operator to prevent excessive power surges and the resultant excessive pressures or heating rates. These restrictions are generally in the form of electrical interlocks in the control circuit. For example, a typical interlock might prevent the operator from concentrating fuel if instruments indicated that an excessive concentration was being reached, or an interlock might stop the addition of fuel solution if the temperature-measuring devices indicated too high a heating rate. Although practically none of these mistakes is serious enough to cause a reactor accident, they are evidence of poor operating technique, and if permitted might result in more serious mistakes which could cause damage in spite of the inherent stability of an aqueous homogeneous system.

The reactor is considered "started up" when the desired operating temperature has been achieved and the reactor is ready for power extraction.